The small food flour supply system uses two flour or starch powder supply systems at the same time. It is mainly used for snack foods. The dough mixer automatically quantifies the dough during mixing. The quantification does not take up the dough mixing time, and a quantification cycle is completed in 3 minutes. , the blanking time is 10–20 seconds, and the quantification is accurate.

Use dust-free feeding and vacuum feeder to lift sesame and powdered sugar into the buffer bin, and then lift into the temporary storage bin after weighing. The flour enters the buffer bin and the online weighing bin under positive pressure to achieve sugar weighing 75 kg and 25 kg of sesame into the mixing tank and mix for 5 minutes, then put in 150kg flour, and repeat the operation for 3 minutes.

The system consists of a feeding station, a buffer storage bin, a vacuum feeder, a pulse dust collector, a weighing bin, etc.

The explosion-proof vibrating screen is suitable for screening flammable and explosive materials. The explosion-proof mark is Ex d IIB T4 Gb/Ex tD A21 IP65 T130℃. It is suitable for the food industry, pharmaceutical industry, chemical industry, metal powder industry, lithium battery industry and other industries.

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line

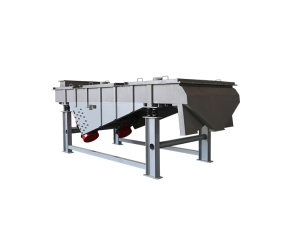

The in-line screen uses a high-frequency vibration motor as the excitation source. After the material enters the system, it undergoes a three-dimensional rotational movement on the screen surface due to the force of the vibration source. The flour and agglomerates are fully dispersed, and quickly pass through the screen and directly enter the lower noodle bin. Impurities and foreign matter are separated and discharged to the slag discharge port, playing the role of “quality assurance officer” on the production line.

The in-line screen can be used in the feeding system at the front end of production lines such as instant noodles, dried noodles, snacks, solid beverages, etc. to separate foreign matter in raw materials (flour, starch, milk powder, additives, etc.). Because it is connected in series in the system and automatically separates foreign matter, it is known as the “quality assurance officer” of the food production line. The flour sifter can replace the manual observation of finding foreign matter and sorting it.

It has unique effects on the screening and classification of powdery and granular materials.

Dewatering screen adopt dual-electrode self-synchronization technology, universal eccentric block, adjustable amplitude vibrator. The machine is combined mainly by the screen box, exciter, support system and motor. The two mutually independent vibrators are respectively driven by the tape coupling to do synchronous reverse operation. The centrifugal force generated by two eccentric masses is superposed along the vibration direction and reversely counteracted, thereby forming a single vibration force along the vibration direction, making the screen box reciprocating linear motion.

Dewatering screen, also known as high-frequency dewatering screen, changing the water surface tension of pulp through the exciting force, pulp water through the screen to become the undersize material, and fine material is blocked by the screen to form the filter layer by the vibration of the forward movement of discharge. Dewatering screen is mainly used for detailings dewatering in the mineral processing industry, coal slurry dehydration of coal preparation plant, washed quartz sand dewatering and ceramic slurry dehydration, and wet and dry classification, dehydration, removal and mud removal of medium and fine granular materials in industrial sectors such as electric power, sugar making and salt making.

The working principle of ZSG heavy vibrating screen is: after the machine starting, a symmetrical arrangement of two vibration motor or excitation device with same model and specifications for synchronous reverse operation, the vibration force through the vibration body – motor or exciter base passed to the whole vibration body – screen box, makes the screen box drives the vibration screen surface to do cyclical movement, so that the material on the surface of the screen to jump sports with screen box, meanwhile, the material smaller than the screen mesh hole will fall to next layer through, becoming the undersize material, the material bigger than the screen mesh hole will be discharged by outlet after continuous jumping movement, eventually completed screening operation.