YK series circular vibrating screen is composition mainly by the screen box, screen mesh, vibrator and damping spring, etc. Vibrator is installed in the side panels of screen box, which driven by motor through the coupling, produce centrifugal inertia force, making the screen box vibration.

The system consists of a bag feeding station, a buffer storage bin, a distribution valve, a weighing bin, and a dough mixer

The system consists of dust-free feeding, vacuum feeder, straight-line screen, buffer storage bin,

mixer, packaging machine, rechecker, inkjet printer, roller conveyor, etc.

The 3D printing material powder is put into the airtight material bucket in advance. The valve below the material bucket can control the passing speed of the powder. The powder enters the vibrating feeder below, and the vibrating feeder uniformly transports the material to the ultrasonic vibrating screen through vibration. The ultrasonic vibrating screen generates three-dimensional motion through the vibrating motor, which forces the material to jump and roll on a certain track on the screen.

This salt crusher machine toothed model works largely with shear force and less crushing. Crushing gap can be adjusted within certain range.

This machine is composed by frame, gear roller, transmission device and gear roller gap adjustment device and so on. Adopting alternating current motor to drive the coarse broken tooth roller on the both sides by the strong triangular belt respectively, so that the coarse broken tooth roller rotates in opposite directions. After the material enters the crushing chamber from the inlet, the two coarse roller is broken by a variety of different combinations broken which are rotated at a high speed, the partical size can be reach to around 6mm after fine broken, the size of particle size can be adjusted by fine teeth roller gap to complete.

This machine is composed by frame, gear roller, transmission device and gear roller gap adjustment device and so on. Adopting alternating current motor to drive the coarse broken tooth roller on the both sides by the strong triangular belt respectively, so that the coarse broken tooth roller rotates in opposite directions. After the material enters the crushing chamber from the inlet, the two coarse roller is broken by a variety of different combinations broken which are rotated at a high speed, the partical size can be reach to around 6mm after fine broken, the size of particle size can be adjusted by fine teeth roller gap to complete.

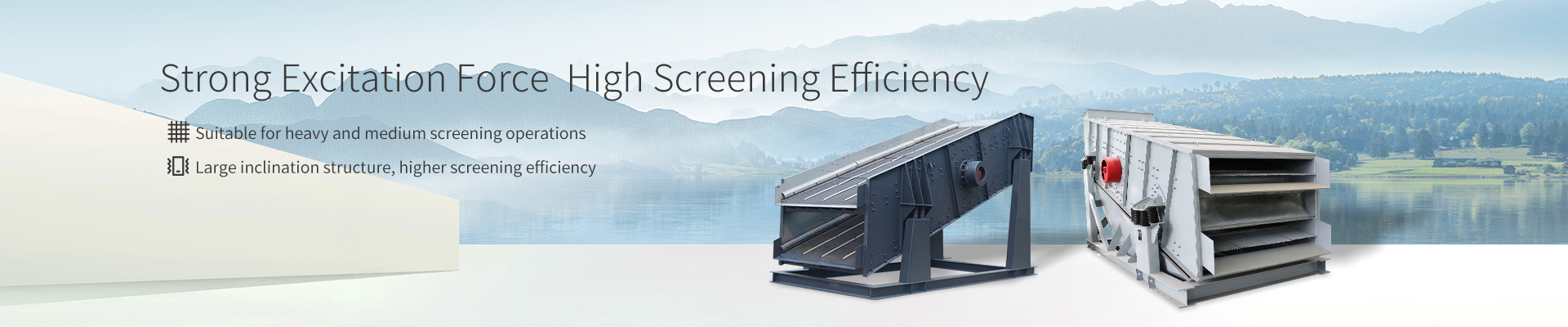

The banana-shaped vibrating screen is a self-synchronizing heavy-duty equal-thickness screen. The screen box is similar to the shape of a banana. The screen beam adopts a box-shaped beam. The vibrating screen transmission system consists of a motor passing through a pulley and a V-belt, and then a universal connecting shaft transmits the energy to the vibration screen. The vibrator and the exciter are connected by an intermediate transmission shaft. The screen surface adopts the form of fold lines with different inclination angles, and the thickness of the material layer does not change from the inlet end to the outlet end. The material volume and flow rate ratio on each section of the screen surface is stable, the material layer is high, and the material is in a uniform state. The screening efficiency is significantly improved, and the processing capacity is 1-2 times higher than that of the vibrating screen with the same effective area. For materials with high fine particle content, especially When the content of materials whose medium content accounts for less than 1/2 of the classified particle size is large, the banana-type vibrating screener has higher screening efficiency.

When BTS bar screen work, the exciting force generated by the vibration exciter through the screen box to pass through to the screen surface, because the exciter vibration force generated by the longitudinal force, fForcing the sieve box to drive the sieve surface to make longitudinal before and after displacement. Under certain conditions, the material on the screen surface is thrown forward due to the exciting force, and the material smaller than the screen hole will fall down through the screen to the lower layer. The BTS bar vibrating screen material’s movement on the screen surface is parabolic, and the bar vibrating screen performs the material screening operation due to such repeated movement of the material.