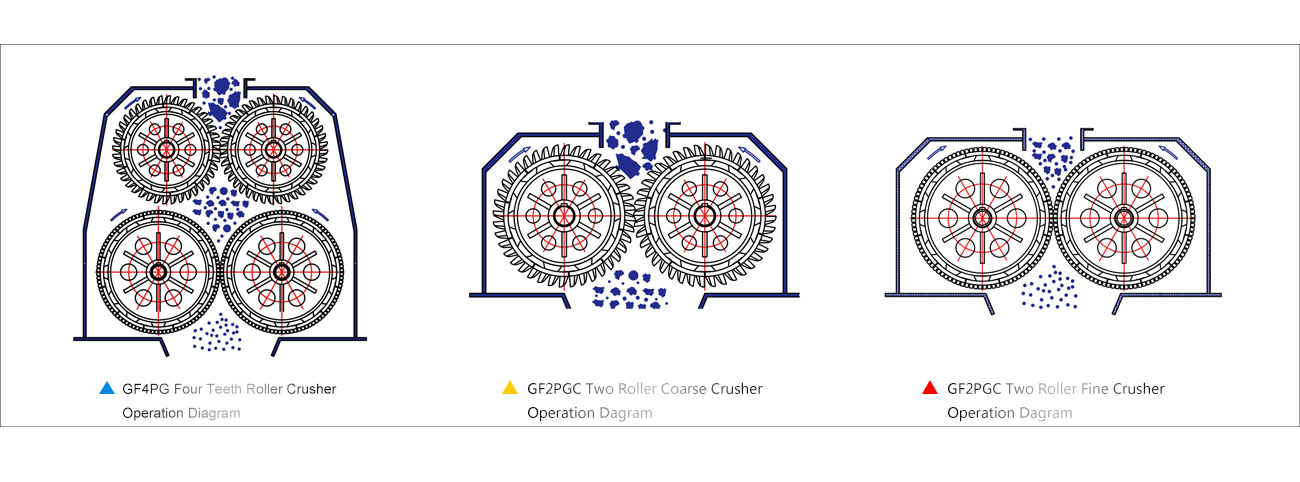

Home / Products / Crushing Equipment / Two Roller Coarse Crusher

Application: Thermal power plants, Thermal companies, Coal fields, etc

Material: Coal, coal gangue, lignite, anthracite, peat, sinter, coke, slag, shale, limestone, etc

|

High Yield Screening

|

Crushing Rate Low, Grain Size Fine

|

|

| Relative roller differential speed operation with mutual scraping action, because of its higher running speed, and also has role of “former pulling back pressure, former blowing back inhaling”, the crusher has no requirement of moisture and mud content in any time, will not affect the crushing effect. Material is always all into the whole out to ensure overfill force. | Crushing rate low, grain size fine: adopting combined crushing but not impact and strike breaking, it will not produce secondary crushing phenomenon, so crushing rate very low. Two teeth roller center distance will not change once fixed, the materials will be hard crushed instantly, almost no repeat broken, to ensure uniform granule. | |

|

Low Investment Costs

|

Simple Structure With Less Maintenance

|

|

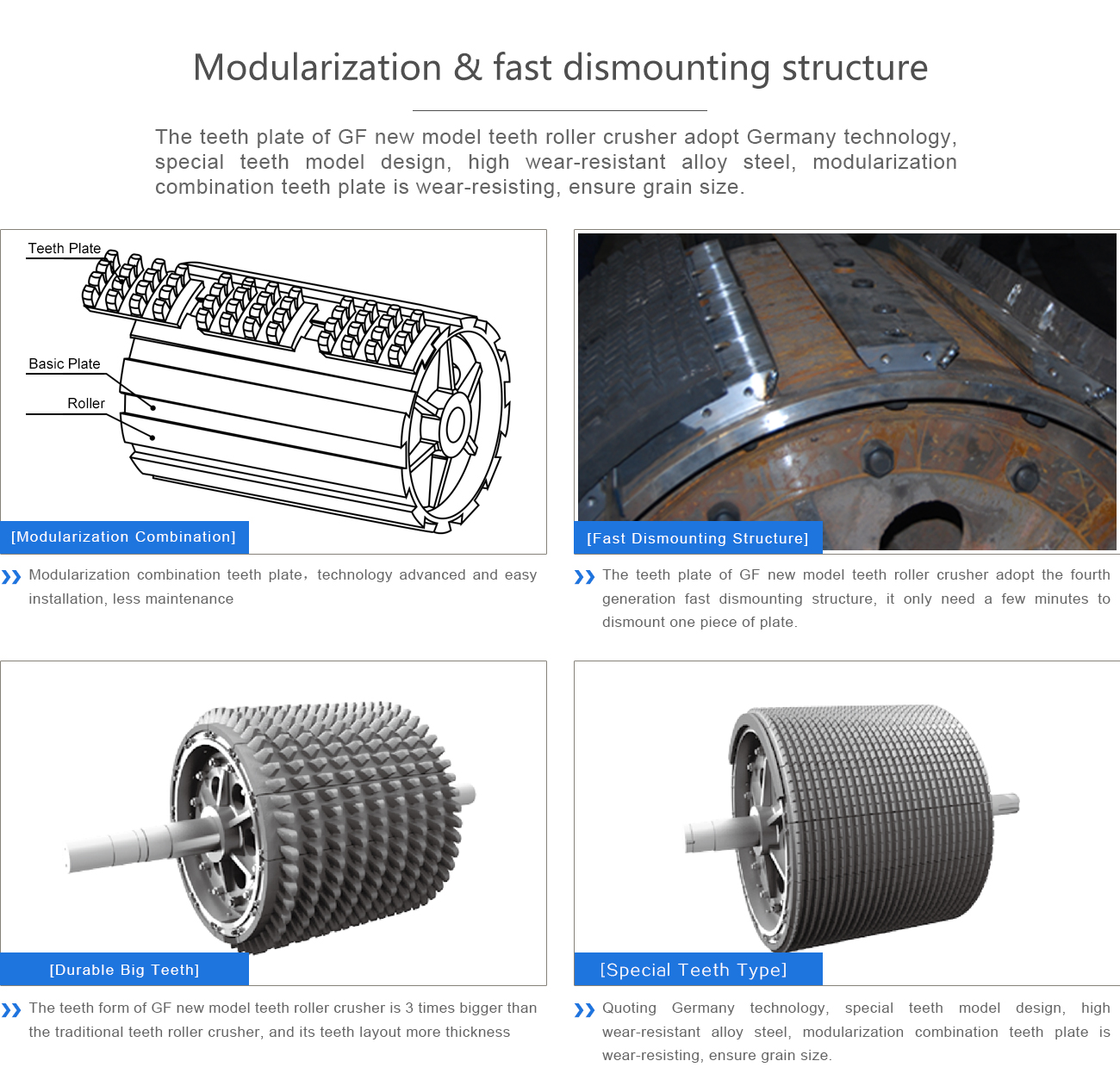

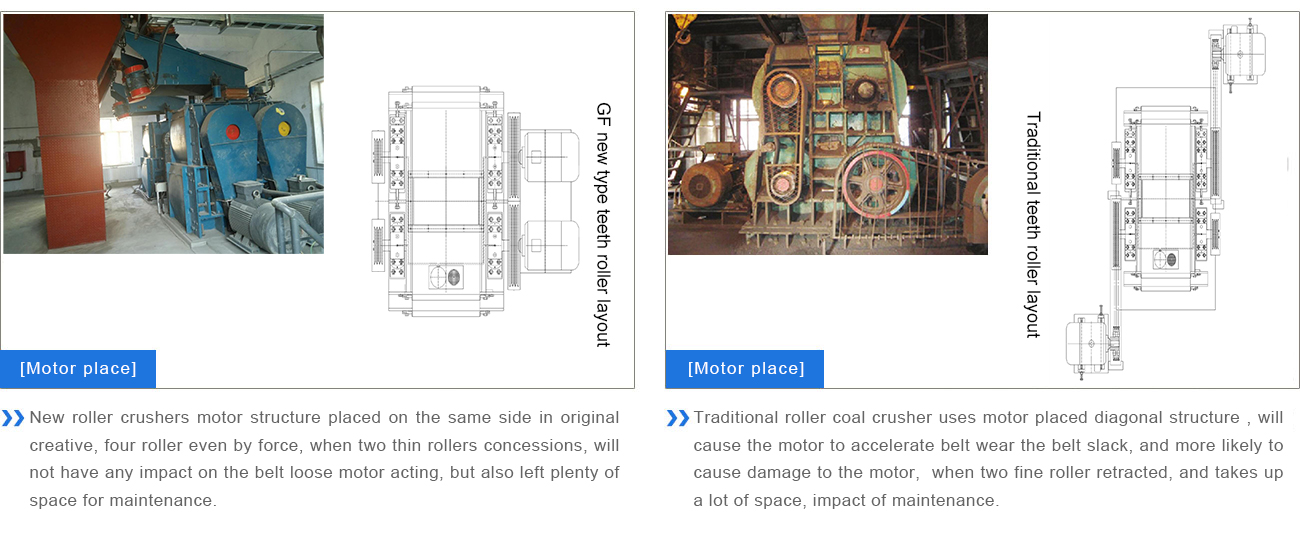

| Screen and crush together, a small investment: two teeth roller relative rotation form rotary space lattice sieve. To achieve the double effect of crushing and screening, one machine can complete the crushing and screening work. So, you don’t need to match the screening equipment, simplifying system, reduce investment cost. | Handwheel or hydraulic structure can adjust the discharging granularity quickly.The equipment adopt modular architecture, can be divided remote installation according to the site requirement, or customer can choose assembly installation, so as to lift and maintain conveniently. Standard modular composite teeth plate more interchangeability and versatility, greatly reduce the replacement cycle of the teeth plate and operating costs. | |

|

Environmental Protection & Energy Saving

|

Integrated Liquid Spring Balance Flashback Protection

|

|

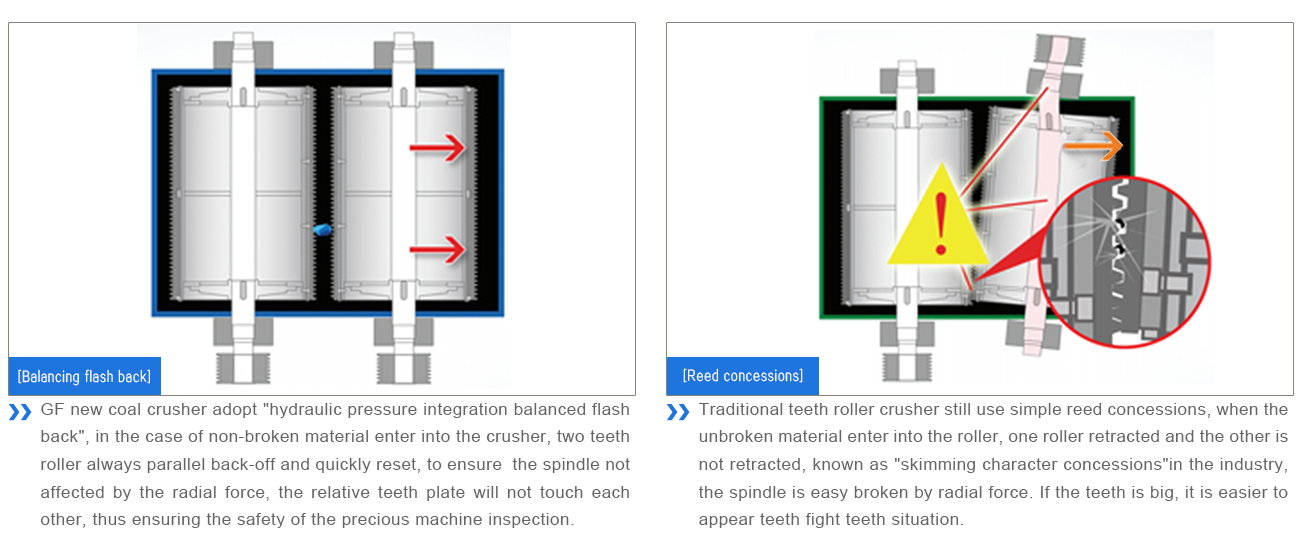

| Input size≤350mm, the outlet between 3-50 mm can be freely adjusted, a crushing ratio can reach 50.GF crusher machine energy consumption has a function of reserve and kinetic energy release.Less than 0.03mm amplitude and below 70 decibels noise, the micro positive pressure and all enclosed structure forms, completely eliminate the work-site “three evils” phenomenon, prevent workers silicosis, it is truly environmentally friendly products. | My company develops automatic concession crusher patented product for the current condition that the coal source is not fixed and more debris . When the wood and other non-magnetic alloy or rubber and other flexible objects can not be broken in the crusher, the two roller quickly and automatically retreat parallel to the above materials, and then quickly returned to the original gap position, to keep continuous operation. | |

|

Safe & Intelligent Reliability

|

Uniform Feeding & Long Service Life

|

|

| GF2PGC Two roller coarse crusher is security smart and reliable: the machine adopts the double protection of the electrical and mechanical, cabinet is equipped with PLC programmable controller, which has the interlock protection function, can achieve local control and centralized control room manual / automatic control. It is a ideal crusher for the heating and powering. | Vibration feeding, uniform distribution: choosing our company’s new type anti-adhesion and anti-blocking vibration uniform feeder, reduce the tooth plate eccentric wear, prolong the life of the tooth plate |

GF2PGC Two Roller Coarse Crusher Parameters(Input size≤250mm, output size≤50mm.)

| Model | Capacity(t/h) | Motor model | Power(KW) | Dimensions(L*W*H) | Weight(Kg) |

| GF2PGC-120 | 100-140 | Y2-200L2-6 | 22×2=44 | 4300×1630×1000 | 8050 |

| GF2PGC-160 | 150-180 | Y2-225M-6 | 30×2=60 | 4300×1830×1000 | 9250 |

| GF2PGC-200 | 180-200 | Y2-250M-6 | 37×2=74 | 4300×2130×1000 | 10500 |

| GF2PGC-230 | 200-250 | Y2-280S-6 | 45×2=90 | 4500×1970×1200 | 12500 |

| GF2PGC-250 | 220-270 | Y2-280S-6 | 45×2=90 | 4500×2480×1200 | 13250 |

| GF2PGC-300 | 260-320 | Y2-280M-6 | 55×2=110 | 4500×2480×1200 | 14050 |

| GF2PGC-370 | 320-390 | Y2-315S-6 | 75×2=150 | 4500×2790×1200 | 16150 |

| GF2PGC-450 | 380-460 | Y2-315S-6 | 75×2=150 | 4550×3090×1200 | 18250 |

| GF2PGC-500 | 450-520 | Y2-315M-6 | 90×2=180 | 4550×3290×1200 | 20350 |

YK series circular vibrating screen is composition mainly by the screen box, screen mesh, vibrator and damping spring, etc. Vibrator is installed in the side panels of screen box, which driven by motor through the coupling, produce centrifugal inertia force, making the screen box vibration.

The DCB environmental protection screen series vibrating screen adopts the reverse self-synchronizing driving mode of two vibration motors, which has better stability. The screen is fixed with a positioning pin at one end. The hook plate at the other end is tightened and fastened. Its unique screen fixing form makes the screen replacement extremely convenient and fast.

The working principle of ZSG heavy vibrating screen is: after the machine starting, a symmetrical arrangement of two vibration motor or excitation device with same model and specifications for synchronous reverse operation, the vibration force through the vibration body – motor or exciter base passed to the whole vibration body – screen box, makes the screen box drives the vibration screen surface to do cyclical movement, so that the material on the surface of the screen to jump sports with screen box, meanwhile, the material smaller than the screen mesh hole will fall to next layer through, becoming the undersize material, the material bigger than the screen mesh hole will be discharged by outlet after continuous jumping movement, eventually completed screening operation.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible