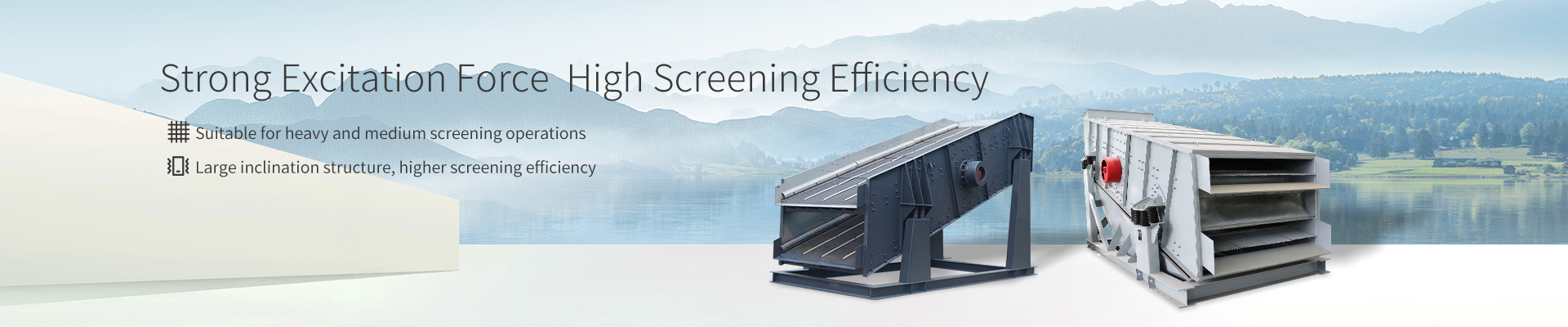

Home / Products / Mine Screening / Heavy Vibrating Screen

Product advantages

Mining, coal, electric power, metallurgy, building materials, refractory materials.

Raw coal, petroleum coke, tailings sand, broken glass, limestone coal, dried sludge, barite, carbon, construction waste, potassium feldspar, etc.

Technical parameters of vibration motor type

| Model | L(mm) | B(mm) | H(mm) | Input size(mm) | Capacity(t/h) | Motor model | Power(KW) | Weight(KG) | Amplitude(mm) |

| ZSG918 | 1810 | 1420 | 1575 | ≤120 | 50~100 | YZO-20-6 | 1.5X2 | 1710 | 5~10 |

| ZSG0924 | 2400 | 1370 | 1630 | 50~100 | YZO-20-6 | 1.5X2 | 1900 | ||

| ZSG1020 | 2000 | 1620 | 1584 | ≤150 | 50~100 | YZO-20-6 | 1.5X2 | 2070 | |

| ZSG1030 | 3000 | 1620 | 1800 | 50~100 | YZO-25-6 | 1.8X2 | 2630 | ||

| ZSG1224 | 2400 | 2190 | 1320 | 80~200 | YZO-30-6 | 2.2X2 | 2300 | ||

| ZSG1230 | 3000 | 2190 | 1800 | 80~200 | YZO-40-6 | 3.0X2 | 2863 | 8~12 | |

| ZSG1530 | 3000 | 2490 | 2180 | 120~300 | YZO-50-6 | 3.7X2 | 3690 | 5~10 |

Technical parameters of exciter type

| Model | Area(m2) | Input size(mm) | Capacity(t/h) | Amplitude(mm) | Exciter model | Power(kw) | L(mm) | B(mm) | H(mm) |

| ZSG1536 | 5.4 | <200 | 50-360 | 8-12 | JZ-75-6 | 2×4.0 | 3675 | 2660 | 2220 |

| ZSG1540 | 6 | 50-400 | JZ-75-6 | 2×4.0 | 4000 | 2660 | 2300 | ||

| ZSG1836 | 6.48 | 60-460 | JZ-100-6 | 2×5.5 | 3620 | 3140 | 2230 | ||

| ZSG1848 | 8.64 | 80-500 | JZ-130-6 | 2×5.5 | 4800 | 3140 | 2950 | ||

| ZSG2040 | 8 | 80-560 | JZ-130-6 | 2×5.5 | 4000 | 3160 | 2300 | ||

| ZSG2050 | 10 | 90-600 | JZ-160-6 | 2×7.5 | 5000 | 3260 | 2730 | ||

| 2ZSG1536 | 5.4 | 50-360 | JZ-160-6 | 2×5.5 | 3675 | 2660 | 2340 | ||

| 2ZSG1540 | 6 | 50-400 | JZ-100-6 | 2×5.5 | 4000 | 2660 | 2700 | ||

| 2ZSG1836 | 6.48 | 60-460 | JZ-130-6 | 2×5.5 | 3620 | 3140 | 2250 | ||

| 2ZSG1848 | 8.64 | 80-500 | JZ-180-6 | 2×7.5 | 4800 | 3140 | 3250 | ||

| 2ZSG2040 | 8 | 80-560 | JZ-180-6 | 2×7.5 | 4000 | 3160 | 2700 | ||

| 2ZSG2050 | 10 | 90-600 | JZ-200-6 | 2×7.5 | 5000 | 3260 | 2940 |

YK series circular vibrating screen is composition mainly by the screen box, screen mesh, vibrator and damping spring, etc. Vibrator is installed in the side panels of screen box, which driven by motor through the coupling, produce centrifugal inertia force, making the screen box vibration.

Dewatering screen adopt dual-electrode self-synchronization technology, universal eccentric block, adjustable amplitude vibrator. The machine is combined mainly by the screen box, exciter, support system and motor. The two mutually independent vibrators are respectively driven by the tape coupling to do synchronous reverse operation. The centrifugal force generated by two eccentric masses is superposed along the vibration direction and reversely counteracted, thereby forming a single vibration force along the vibration direction, making the screen box reciprocating linear motion.

Dewatering screen, also known as high-frequency dewatering screen, changing the water surface tension of pulp through the exciting force, pulp water through the screen to become the undersize material, and fine material is blocked by the screen to form the filter layer by the vibration of the forward movement of discharge. Dewatering screen is mainly used for detailings dewatering in the mineral processing industry, coal slurry dehydration of coal preparation plant, washed quartz sand dewatering and ceramic slurry dehydration, and wet and dry classification, dehydration, removal and mud removal of medium and fine granular materials in industrial sectors such as electric power, sugar making and salt making.

Since the screen shafts are arranged according to different working angles, when the material runs at a higher working angle, the speed is faster; when the material runs at a lower working angle, the speed is slower. Materials running at two different speeds start to move axially when they meet at a certain position on the screen surface. The material layer can be evenly distributed on the screen surface, effectively improving screening efficiency.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible