For waste glass crushing, you only need to add grinding equipment after the crushing production line, and the reuse value will be doubled. The finished…

Soil leaching technology is a soil remediation method that digs out contaminated soil, removes oversized components through screening and divides the soil into coarse materials and fine materials

It is widely used in chemical industry,

building materials, medicine, breeding, food, manufacturing, power generation, and other industries; it can also be made into machine-made charcoal for heating.

During the slicing process of marble blocks, water is added to lubricate the cutter, and the resulting stone chips, stone powder and lubricating water are mixed into a slurry.

The vacuum residue of petroleum is cracked and coked by a coking device at 500 to 550°C to produce black solid coke.

Coal has a wide range of uses, which can be summarized into three main uses according to its purpose: thermal coal, coking coal, coal chemical industry coal,

mainly including coal for gasification, coal for low-temperature carbonization, coal for hydrogenation and liquefaction, etc.

Gaofu slag special dewatering screen has low investment cost, low operating cost, low maintenance cost, few wearing parts, durability and low cost; continuous production,

no manual operation required.

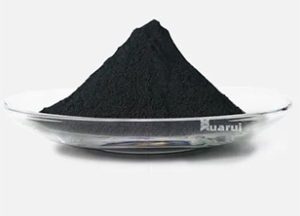

The production process of molybdenum powder is a complex physical and chemical process. Most industrial methods use ammonium molybdate, followed by thermal

decomposition and hydrogen reduction.

An important metal powder in the powder metallurgy industry. Iron powder is used in large quantities in powder metallurgy production, accounting for about 85% of the total

consumption of metal powder