Coal has a wide range of uses, which can be summarized into three main uses according to its purpose: thermal coal, coking coal, coal chemical industry coal, mainly including coal for gasification, coal for low-temperature carbonization, coal for hydrogenation and liquefaction, etc.

(1) Coal for power generation: More than 1/3 of China's coal is used for power generation, and the average coal consumption for power generation is about 370g/(kW·h) of standard coal. Power plants use the calorific value of coal to convert thermal energy into electrical energy.

(2) Coal consumption for steam locomotives: accounting for about 3% of power coal consumption. The average coal consumption index of steam locomotive boilers is about 100kg/(10,000 tons·km).

(3) Coal used for building materials: accounting for more than 13% of coal used for power, with cement using the largest amount of coal, followed by glass, bricks, tiles, etc.

(4) Coal used in general industrial boilers: In addition to thermal power plants and large heating boilers, general enterprises and industrial boilers for heating have many models, large quantities and scattered, and the coal consumption accounts for about 26% of thermal coal.

(5) Domestic coal: The amount of domestic coal is also large, accounting for about 23% of coal used for fuel.

(6) Thermal coal for metallurgy: Thermal coal for metallurgy is mainly anthracite coal for sintering and blast furnace injection, and its consumption is less than 1% of the amount of thermal coal.

Although China is relatively rich in coal resources, its coking coal resources are relatively small. Coking coal reserves only account for 27.65% of China's total coal reserves.

Coking coal includes gas coal (accounting for 13.75%), fat coal (accounting for 3.553%), main coking coal (accounting for 5.26%), lean coal (accounting for 4.01%), and other unclassified coal (accounting for 0.55%); non-coking coal Coking coal includes anthracite (10.93%), lean coal (5.55%), weakly caking coal (1.74%),

non-caking coal (13.8%), long-flame coal (12.52%), and lignite (12.76%). %), natural coke (accounting for 0.3%), unclassified coal (accounting for 13.80%) and coal with unclear brand (accounting for 1.06%).

The main use of coking coal is to make coke. Coke is smelted at high temperature from coking coal or mixed coal. Generally, about 1.3 tons of coking coal can be used to make one ton of coke. Coke is mostly used in steelmaking and is the main raw material for steel and other industries. It is known as the "basic food" of the steel industry.

It can also be used as fuel, but when used as fuel, a graded impact mill is required for ultrafine pulverization. The coke powder can only be burned after being made into coke powder through the equipment, and the coke powder is used as fuel.

The crushed coal has a uniform particle size, generally 8-100mm, which can fully burn coal and ensure emissions meet standards.

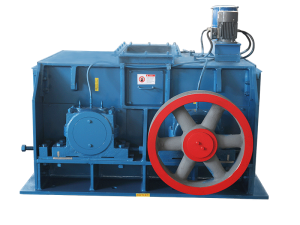

This machine is composed by frame, gear roller, transmission device and gear roller gap adjustment device and so on. Adopting alternating current motor to drive the coarse broken tooth roller on the both sides by the strong triangular belt respectively, so that the coarse broken tooth roller rotates in opposite directions. After the material enters the crushing chamber from the inlet, the two coarse roller is broken by a variety of different combinations broken which are rotated at a high speed, the partical size can be reach to around 6mm after fine broken, the size of particle size can be adjusted by fine teeth roller gap to complete.

This machine is composed by frame, gear roller, transmission device and gear roller gap adjustment device and so on. Adopting alternating current motor to drive the coarse broken tooth roller on the both sides by the strong triangular belt respectively, so that the coarse broken tooth roller rotates in opposite directions. After the material enters the crushing chamber from the inlet, the two coarse roller is broken by a variety of different combinations broken which are rotated at a high speed, the partical size can be reach to around 6mm after fine broken, the size of particle size can be adjusted by fine teeth roller gap to complete.

GF4PG four teeth roller crusher is composed by teeth roller with high speed and strength to do the opposite running. The material free fall as meet the gap of teeth roller, the material bigger than two teeth roller gap will be instantly broken and free fall, to achieve the crushing purpose, meet the size requirements. Relative roller with differential operation can cleaning each slot of the material, so as to prevent sticking, blocking phenomenon and make the material without staying on the surface to avoid a repeat broken, avoid over – crushed.