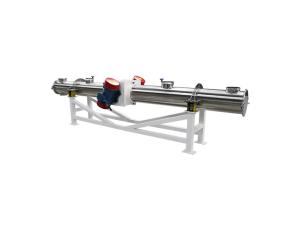

The tubular vibrating feeder is a linear vibrating inertial conveyor. The width and depth of the trough determine its processing capacity, and the effective length of the trough determines its conveying distance. It has the characteristics of simple and compact structure, uniform and continuous feeding, and easy maintenance.

Shipping and storage containers for medium handling volumes. In addition, they are particularly suitable for use as mobile bagged bulk storage containers that can be automated. Bulk materials are transferred into containers through corresponding conversion stations.

The composite magnetic system is composed of high-performance hard magnetic materials. It has the characteristics of high magnetic field intensity, large depth, simple structure, easy to use, no maintenance, no power consumption, and no demagnetization after long-term use.

Suitable for chemical raw materials, toxic, harmful, poor fluidity materials, etc.

The air flow screen in the air path adopts a closed design. After screening rubber additives, light calcium and other materials, the measured output is 1 ton/㎡/H, the screening efficiency is over 95%, and the dust content in the air is less than 10 mg./m³, which solves the problem of dust flying

Using airflow to atomize raw materials into monomers can solve problems such as black spot removal, stickiness, agglomeration, dust, and pollution, which can improve product purity and improve product quality.

Used for screening and classifying materials that are flammable, explosive, easily oxidized or harmful to the human body

Suitable for food processing enterprises that need automated production and truly solve environmental protection and safety issues