High output: 5-10 times or higher than that of vibrating screen

High efficiency: Screening efficiency is as high as 95% or more;

Conjunction with various equipment: Can be used with various mills and wind turbines connected to the grid;

Cost savings: Low noise, low energy consumption, continuous operation, and reduced maintenance.

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, other industries, etc.

Zinc powder, graphite powder, resin powder, traditional Chinese medicine powder, coating, fly ash, wood powder, rubber additives, talc powder, mica powder, API, pharmaceutical intermediates, cosmetics, fire extinguishing agent, plastic powder, clay, abrasives , aluminum powder, glass powder, refractory materials, starch, milk powder, metallurgical powder, electromagnetic materials, copper powder, carbon black, activated carbon, light calcium carbonate, heavy calcium carbonate, iron ore, magnetic materials, zinc borate, hydroxyethyl cellulose, magnesium oxide, light magnesium oxide, barium sulfate, zinc oxide, manganese dioxide, rubber powder, active enzymes, molecular sieve raw materials, starch, pigments, PVC resin powder, silica gel powder, battery materials,lithium iron phosphate, lithium manganate, lithium cobalt oxide and other powder materials.

| Model | airflow volume (m³/h) |

Screen specifications (mesh) |

Feeding particle size (mesh) |

Power (kW) |

Spindle speed (r.p.m) |

Cage diameter (mm) |

Cage length (mm) |

| WS-600 | 240-1100 | 80-600mesh | 40mesh≤ | 3 | 420 | Φ606 | 380 |

| WS-1000 | 200-2500 | 5.5/7.5 | 960 | Φ1006 | 730 | ||

| WS-1600 | 500-2600 | 11/15 | 970 | Φ1500 | 2335 | ||

| WS-1800 | 720-7200 | 22 | 650 | Φ1800 | 1802 |

It is connected in series in the air path of raw material production. The raw material mixture enters the machine body from the air flow screen inlet. Through the intelligent turbine, the raw materials are dispersed into monomers and pass through the composite screen in an orderly manner, and then enter the next process along the wind path. Unqualified impurities and foreign matter are intercepted and automatically discharged through the automatic slag discharge port. This completes the selection process of networked jobs. Using airflow atomization to disperse raw materials into monomers, it overcomes the stickiness, agglomeration, electrostatic adsorption, light weight, floating, agglomeration and other characteristics of materials that are difficult to screen, and achieves the purpose of effective screening that cannot be achieved by traditional screening machinery. It is an intelligent screening equipment that comprehensively utilizes centrifugal force, wind force, gas vortex, mechanical kinetic energy, gravitational potential energy and vibration force.

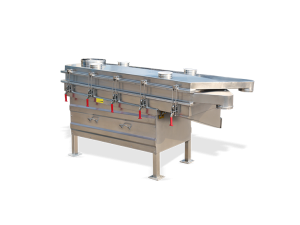

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

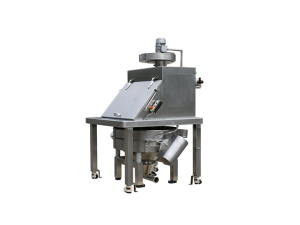

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible