The pigments are a substance that makes an object color. Pigments are soluble and insoluble, with inorganic and organic differences. Inorganic pigments are generally mineral substances. It has long been known that humans use inorganic pigments to paint and smear the body on colored walls using colored soil and ore. Organic pigments are generally obtained from plants and marine animals such as indigo, garcinia, and purple extracted from shellfish in ancient Rome.

The pigments are a substance that makes an object color. Pigments are soluble and insoluble, with inorganic and organic differences. Inorganic pigments are generally mineral substances. It has long been known that humans use inorganic pigments to paint and smear the body on colored walls using colored soil and ore. Organic pigments are generally obtained from plants and marine animals such as indigo, garcinia, and purple extracted from shellfish in ancient Rome.

Pigment production process

Crushing--drying--conveying--screening--packaging

Sieving aim

In the air flow drying, air flow grinding, air flow wind selection, air separation and air separation crushed, a matching centrifugal sifter can be added to achieve the purpose of filtering and removing impurities. It is of course also possible to add the centrifugal sifter system separately.

Pigment screening problem

The fineness of powder pigments are important factors affecting its quality and market value. Therefore, in the pigment production process, the screening process is the most important link, but due to the characteristics of large pigment viscosity and easy grouping, the phenomenon of pigment bundling and blocking the mesh during the screening process is particularly serious. At the same time, the use of traditional screening process on-site dust flying, environmental pollution, raw material loss and other issues have also been a major problem in pigment production.

Problems with pigment production

In the process of industrial pigment production, the whole set of production equipment system is tight and the equipment is sophisticated and advanced, but the produced products are directly into the packaging machine, often because the industrial impurities in the products directly affect the product quality, and the customer requests compensation when exporting. How to ensure the quality of the product? Purchasing and selecting reasonable equipment is the fundamental condition for ensuring the product, so the product must be sieved before packaging. This is the only choice, but the pigments are generally nano-scale fineness, sticky and light, to agglomerate into particles. Sometimes the dust is large, which wastes raw materials and pollutes the environment. A general sieve machine cannot solve the screening problem. It is a perfect strategy to use the special centrifugal sifter for pigment removal. After the use of Hangzhou Lily Clarian Paint Co., Ltd., Tianjin Organic Chemicals, Jinchuan Group, etc., the effect is very good. "It's like adding another lung to the system and purifying the foreign material," one client said. The specific operation method is very simple. A complete centrifugal sifter is added in the air flow drying, air flow grinding, air flow air selection and air separation crushing wind path, then it can achieve the purpose of filtering and removing impurities. It is of course also possible to add the air flow screen system separately. When you see the impurities in the screen, there are signs, thread ends, agglomerates, foreign matter such as oxidized foreign bodies, screws, hair strands, etc. You can safely say that the quality of our products is absolutely no problem and safe. The company's product quality is stable.

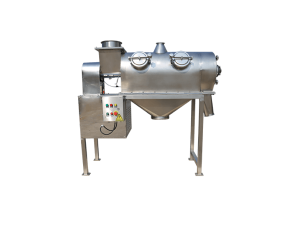

Introduction of pigment special screening machine system

Gaofu Company has developed and produced a pigment-specific screening machine system for the characteristics of pigments. Because the special screen for pigments adopts vertical loading and air atomization and jetting technology, it solves the problem of large viscosity of the pigment and easy to block the screen; in the airway of airflow drying, airflow milling, airflow selection and air separation, Adding special pigment-specific sieves, the whole screening system adopts negative pressure cycle design, and then adds equipment such as dust collectors, which solves the problem of dust and pollution, eliminates waste of raw materials, and achieves environmental cleanliness and economic value.

Zhejiang hangzhou baihe clariant pigments co., LTD

Tianjin organic one

Jinchuan,

In fine chemical industry

Merida pigment industry co., LTD

Shanghai yan titanium industry co., LTD

Numerous chang hengtai powder pigment co., LTD

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.