Home / Products / Fine Screening / Vertical Airflow Sieve

High flow rate: WS series air flow screening machine mixes gas and atomizes to pass through the mesh and is equipped with vibration force at the same time

Wide range fineness: Powdery materials of 80-600 mesh can be screened efficiently

Long service life: The screen is installed vertically, without load bearing, and has a long service life

No pollution: The screening system is carried out under negative pressure semi-circulation state, without dust pollution

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, other industries, etc.

Rubber powder, magnetic materials, rubber additives, calcium powder (light calcium, heavy calcium), zinc powder, activated calcium, hawthorn powder, iron oxide black, iron oxide red, traditional Chinese medicine powder, quartz powder, carbon black, silicon dioxide, etc.

| Model | Airflow volume (m³/h) |

Screen specifications (mesh) |

Feeding particle size (mesh) |

Power (kW) |

Spindle speed (r.p.m) |

Cage diameter (mm) |

Cage length (mm) |

| WS-600 | 240-1100 | 80-600mesh | 40mesh≤ | 3 | 1420 | Φ606 | 1380 |

| WS-1000 | 200-2500 | 5.5/7.5 | 960 | Φ1006 | 1730 | ||

| WS-1600 | 500-2600 | 11/15 | 970 | Φ1500 | 2335 | ||

| WS-1800 | 720-7200 | 22 | 650 | Φ1800 | 1802 |

The air flow screen abandons the operating principle of gravity potential energy and uses air as the carrier and the operating principle of kinetic energy as work. The raw material mixture enters the machine body from the air flow inlet, and is powered by an intelligent turbine to cause the raw material dispersed monomers to pass through the composite screen in an orderly manner, and then enter the next process along the wind path. Unqualified impurities and foreign matter are intercepted and discharged through the automatic slag discharge port. This completes the selection process of networked jobs.

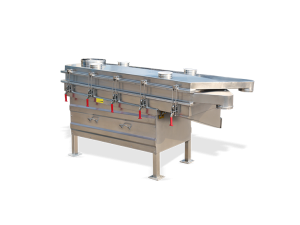

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible