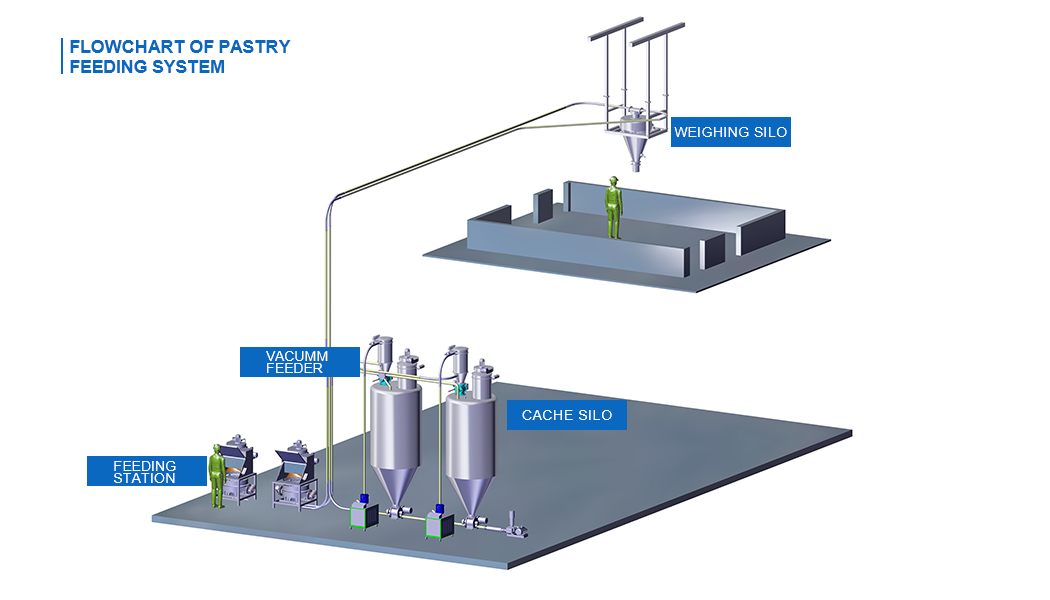

Home / Products / System equipment / Food powder supply system / Pastry feeding system

Material: Flour, powdered sugar, etc.

Capacity: 150kg

System interpretation

System interpretation● The dust-free feeding and vacuum feeding machine lifts the flour and powdered sugar into the buffer bin, and then performs online weighing through positive pressure to realize the weighing of 30-60 kg white sugar into the mixing tank and mix for 60-90S, then add 50-90 kg flour and mix for 8 minutes to repeat the operation.

| Item | Description | Save |

| Artificial | New technology can save 4 people; The new process only needs: 1 person for feeding, 1 person for beating, saving 1 person for noodle delivery, 1 person for sesame and sugar, 1 person for operator, 1 person for batching; |

It can save 240,000 yuan of labor cost every year; (solve the problem of difficult recruitment) According to the per capita 5,000 yuan/month, 4 people * 5,000 yuan * 12 = 240,000 yuan; |

| Environmental protection | The new technology connects each equipment with pipelines, and the whole process is dust-free, meets environmental protection A-level requirements, and does not stop production throughout the year; The old technology is dusty, and there is a hidden danger of dust explosion. |

Can avoid more than 2.5 million losses; For example: the old craft needs to stop production when the red and orange warnings are issued. If the production is stopped for 50 days, the loss will be 2.5 million; The hidden danger of dust explosion is not calculated; |

| Safety | New process pipeline sealed connection, no dust and safer; | Dust from old technology can easily cause dust explosion. |

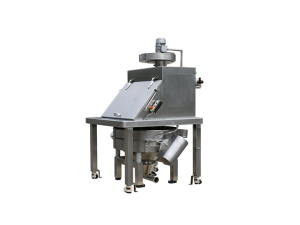

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

It is suitable for single-layer screening and filtration by manufacturers in various industries to process materials with low production volume or low impurities.

It is suitable for many industries such as medicine, foodstuff, chemical industry, metallurgy and building material, aiming at the confinement transportation of various powder materials, improving the cleanliness of materials, which can meet the diversified transportation needs of different customers.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible