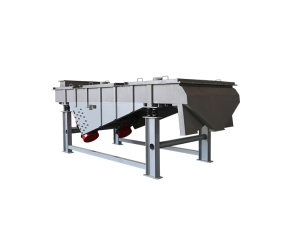

It has unique effects on the screening and classification of powdery and granular materials.

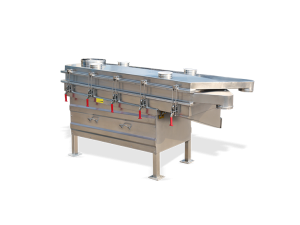

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo.

The solid-liquid separation centrifugal screen can handle oversized solid particles in the form of plant fibers, intercept and recycle purified resin particles, and intercept mixture agglomerations, etc.

It is widely used in scientific research, production and laboratories in geology, metallurgy, abrasives, powders, chemicals, construction cement, medicine, national defense and other departments to screen and test materials.

High screening accuracy and accurate detection results. Suitable for particle shape, particle size distribution and various detection

It adopts the principle of plane gyration motion, which reduces the dynamic to static ratio and basic dynamic load of the equipment, improves the screening efficiency of qualified materials, and thus increases profits.

The environmentally friendly dust-free vibrating screen is a clean and environmentally friendly screening device. It is designed to achieve the purpose of removing impurities in raw materials and classifying them in a fully balanced and sealed condition.

The air flow screen in the air path adopts a closed design. After screening rubber additives, light calcium and other materials, the measured output is 1 ton/㎡/H, the screening efficiency is over 95%, and the dust content in the air is less than 10 mg./m³, which solves the problem of dust flying