Home / Products / Fine Screening / Solid-liquid Separation Centrifugal Sifter

Remove impurities: Remove slurry residue and plant fibers in the original pulp;

No omissions: Fully enclosed design;

High efficiency: High flow rate, production capacity up to 10-100 m³/hour;

Long service life: Unique process can extend the life of filters by 5-10 times

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, other industries, etc.

GFYL solid-liquid separation centrifugal screen is an ideal choice for separating solid matter from large amounts of liquid slurry. It is often used to process plant fibers in biological extraction liquids or reduce product loss and reduce the cost of sewage treatment. Gaofu’s staff have extensive professional application knowledge and experience to ensure that the equipment selected meets your processing needs. GFYL solid-liquid separation centrifugal screen is an upgraded version based on the traditional centrifuge principle. This equipment has many uses. It can handle oversized solid particles in the form of plant fibers, intercept and recover purified resin particles, and intercept mixture agglomerations, etc. The centrifugal action of the impeller enables the solid-liquid separator to achieve high-precision and high-efficiency separation, and the mesh fineness can reach 20 microns.

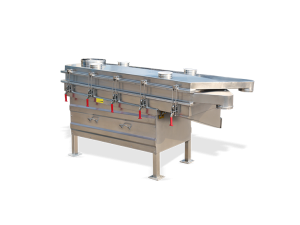

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

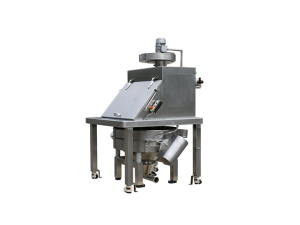

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible