Strong ability: Especially suitable for the production and grading process of diamond powder and super-hard material industries, and can be used repeatedly with high intensity and frequency.

Wide range: Widely used in scientific research, production and laboratories in geology, metallurgy, abrasives, powders, chemicals, construction cement, medicine, national defense and other departments

Automatic shutdown: Equipped with a variety of clamps, the clamping is flexible and firm, and can automatically shut down

Screening and testing of solid materials in scientific research and production laboratories of geology, metallurgy, abrasives, powders, chemicals, construction, cement, medicine, national defense and other departments

Grading and particle size inspection of abrasives, super-hard materials and other products

| Name | Value |

| Shaking(times/m) | 290±5 |

| Impact numbers (times/m) | 110±4 |

| Impact height (mm ) | 38±6 |

| Reciprocating stroke( mm ) | 25 |

| Sieve diameter( mm ) | Φ200 Φ75 Φ100 |

| Layer (s ) | 5 |

| Motor power( W ) | 370 |

| Motor speed( mm ) | 1400 |

| Motor voltage( v ) | 380 |

| Overall dimension (mm ) | 350(L)×450(W)×785(H) |

| Total weight (kg ) | 190 |

Adopt Y series three-phase asynchronous motor. The power drive the worm gear and the worm variable speed institutions movement through the coupling transmission, so that the rotating vertical shaft and the camshaft rotate respectively, causing the horizontal circular movement of the sieve and driving the jack to lift and push the slap of the slamming hammer simultaneously. Material produces a circle motion on the screen surface by force, while the striking force of the hammer hit produce jump, tumbling. Finally, the screening process can be completed according to the sieve hole size, to achieve the inspection and classification purpose.

Using airflow to atomize raw materials into monomers can solve problems such as black spot removal, stickiness, agglomeration, dust, and pollution, which can improve product purity and improve product quality.

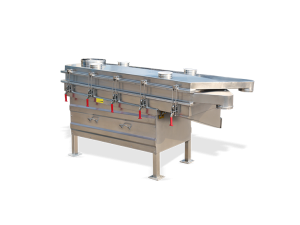

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible