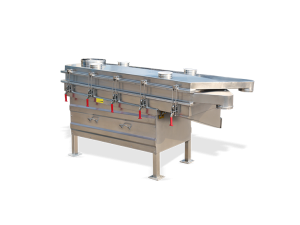

Home / Products / Fine Screening / Flat Gyratory Screen

Precise screening: Higher particle accuracy and higher output

Flexible screening: Low-angle rotary reciprocating motion, flexible screening of materials, effectively reducing damage to fragile materials

Automatic cleaning: The screen cleaning ball rotates and reciprocates to keep the screen clear, prevent clogging, and prevent the screen from sticking

Stable performance: Provides long-term, trouble-free service with less maintenance

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, other industries, etc.

Sugar, salt, monosodium glutamate, chicken essence, glucose, amino acids, potassium sorbate, bread crumbs, freeze-dried food, coconut pellets, frozen dumplings, granular pills, pellets, traditional Chinese medicine pieces, iron powder, aluminum powder, lead powder, copper powder , alloy powder, electrolytic copper powder, refractory materials, steel shot, alumina, metal metallurgical powder, sodium bicarbonate (soda ash), etc.

| Model | Screen area(m²) | Layer | Feed size(mm) | Amplitude(s) | Speed(r/min) | Power(kW) |

| HXS-1224 | 1200×2400 | 1~3 | ≤15 | 75~90 | 1450 | 5.5 |

| HXS-1236 | 1236×3600 | 1~3 | ||||

| HXS-1530 | 1500×3000 | 1~3 | ||||

| HXS-1536 | 1500×3600 | 1~3 | 750 | |||

| HXS-1836 | 1800×3600 | 1~3 | ≤20 | 7.5 | ||

| HXS-1840 | 1800×4000 | 1~3 | ||||

| HXS-2040 | 2000×4000 | 1~3 | 11 |

gyration reciprocating motionThe cycloidal reciprocating motion transitions gradually along the length of the device, with the cycloidal motion starting at the head and then moving to an elliptical motion in the center and back to reciprocating motion near the end.

1.Circular motion of feed end

2.Change to elliptical motion at center

3.Reciprocating motion of discharge end

Using airflow to atomize raw materials into monomers can solve problems such as black spot removal, stickiness, agglomeration, dust, and pollution, which can improve product purity and improve product quality.

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible