A sweetener is a food additive that imparts sweetness to a soft drink. According to the nutritional value, sweeteners can be divided into nutritive sweeteners (sucrose, glucose, fructose) and non-nutritive sweeteners; according to their sweetness, they can be divided into low-sweet sweeteners and high-sweet sweeteners. According to its source, it can be divided into natural sweeteners (xylitol, sorbitol, mangosteen powder, stevia, maltitol) and synthetic sweeteners (saccharin, sodium saccharin, aspartame).

Sweetener introduction

A sweetener is a food additive that imparts sweetness to a soft drink. According to the nutritional value, sweeteners can be divided into nutritive sweeteners (sucrose, glucose, fructose) and non-nutritive sweeteners; according to their sweetness, they can be divided into low-sweet sweeteners and high-sweet sweeteners. According to its source, it can be divided into natural sweeteners (xylitol, sorbitol, mangosteen powder, stevia, maltitol) and synthetic sweeteners (saccharin, sodium saccharin, aspartame).

Sweetener characteristics

Sweeteners: sweeteners absorb moisture, stability, different properties due to different materials

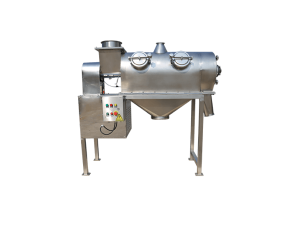

Applicable models: rotary vibrating screen, ultrasonic vibrating screen, linear vibrating screen, air flow sieve, straight screen

Sweetener screening requirements

Screening requirements: impurity & agglomeration removal, classification

Sweetener production process

Production process: crystallization / spray drying

Common material screening purpose and applicable models

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying

Gaofu combines ultrasonic and vibrating screens to solve the problem of difficult screening of highly adsorbent materials.