Plastic is a synthetic polymer, which is also commonly known as plastic or resin, and is free to change its form. The material is the monomer materials synthesis or condensation reaction polymerization, from synthetic resins and fillers, plasticizers, stabilizers, lubricants, pigments and other additives.

Plastic is a synthetic polymer, which is also commonly known as plastic or resin, and is free to change its form. The material is the monomer materials synthesis or condensation reaction polymerization, from synthetic resins and fillers, plasticizers, stabilizers, lubricants, pigments and other additives.

The plastic we usually use is not a pure substance, it is made of many materials.The polymer (or synthetic resin) is the main component of plastic, in addition, in order to improve the performance of the plastic, it needs to add many kinds of auxiliary materials in the polymer, such as filling material, plasticizer, lubricant, stabilizing agent, colorant, etc., to become a good performance plastic.

Synthetic resin is the main ingredient of plastic, its content in plastic is generally 40% to 100%. Due to the large content, and the nature of the resin often determines the properties of the plastic, it is often regarded as a synonym for plastic. For example, polyvinyl chloride resin and polyvinyl chloride plastic, phenolic resin and phenolic plastic confused. In fact, resin and plastic are two different concepts. Resin is an unprocessed virgin polymer that is used not only for plastics, but also for paints, adhesives, and synthetic fibers. In addition to a very small part of the plastic containing 100% of the resin, the vast majority of plastic, in addition to the main component of the resin, but also need to add other substances.

Filling material also known as filling agent, which can improve the strength and heat resistance of plastics, and reduce costs. For example, adding wood powder in phenolic resin can greatly reduce the cost, making phenolic plastic as one of the cheapest plastic, while can significantly improve the mechanical strength. Filling material can be divided into two types of organic filling material and inorganic filling material, the former such as wood flour, rags, paper and various fabric fibers, the latter such as glass fiber, diatomaceous earth, asbestos, carbon black and so on.

Plasticizers can increase the plastic plasticity and softness, reduce brittleness, and make plastic easy to process. Plasticizers are generally miscible with the resin, non-toxic, odorless, light, heat-stable high-boiling organic compounds, the most commonly used is phthalates. For example, when producing polyvinyl chloride plastic, soft polyvinyl chloride plastic can be obtained if more plasticizer is added. If no or less plasticizer is added (less than 10%), rigid polyvinyl chloride plastic can be got.

In order to prevent the synthetic resin decomposition and destruction by the role of light and heat in the processing and use, to extend the service life, it need to be added the plastic stabilizer. Commonly used stearate, epoxy resin and so on.

Colorant can make plastic with various bright and beautiful color.Organic dyes and inorganic pigments are used as colorants.

The purpose of the lubricant is to prevent the plastic from sticking to the metal mold during molding and to make the plastic surface smooth and beautiful. Commonly used lubricants are stearic acid and its calcium and magnesium salts.

Prevent the plastic in the heating molding or the high temperature oxidation, leaving the plastic yellow, cracked, etc.

In addition to the above additives, the plastic can also be added flame retardants, foaming agents, antistatic agents, etc., to meet different requirements.

According to different types of plastic use characteristics, usually divided into Universal plastic plastic, engineering plastic and special plastic.

Generally refers to the large output, wide use, good moldability and cheap plastic. There are five varieties, namely PE, PP, PVC, PS and ABS. They are all thermoplastics.

Generally refers to withstand some external force, has good mechanical properties and high temperature, low temperature performance, dimensional stability is good, can be used as engineering plastics, such as polyamide, polysulfone and so on.

Generally refers to a special function, can be used for aviation, aerospace and other special applications. Such as fluoroplastic and silicone with outstanding high temperature, self-lubricating and other special functions, and enhance plastic and foam with high strength, high cushioning and other special properties, these plastics are all belong to the category of specialty plastics.

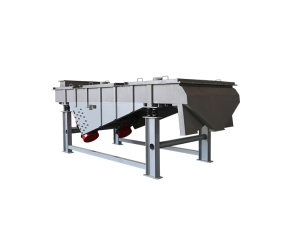

①Raw materials screening: For example: PE, PP, PVC, PS, ABS, etc. Because of their qualitatively homogeneous particles in production, their screening purpose is to remove impurities and agglomerates.

②Recycling and Screening of Scrap Plastic: Forming Plastic Products for Recycling, for example: Waste Plastic Pipe, Scrap Plastic Scaffold, Waste plastic bottle, etc. They need to screen after crushing.

③Plastic particles screening: Molded plastic particles for grading, the screening purpose is precision graded;

④Resin slices screening: Screening is more difficult, because the resin chips easily bond, and there will be a long single unqualified material, you can post some material to test and then clear screening needs;

⑤Filling material screening: wood flour, glass fiber, diatomaceous earth, natural mineral powder, carbon black etc;

1. ECOREMA, S.L.

2. DP “Shinkontrakttorg” dba AR-Plast

3. ALFAKHER FOR PLASTIC INDUSTRIES

4. EESTI PLAST OU

5. ORIENTAL GROUP LTD., Russia

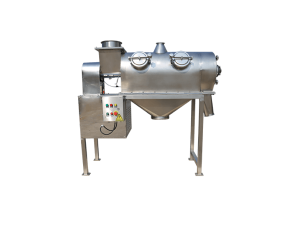

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying

It has unique effects on the screening and classification of powdery and granular materials.