Strong ability: Can be installed and used in three-dimensional and multi-layer, flexible and convenient to move, safe and reliable in continuous operation

High efficiency: Combined with the ultrasonic sieving system, it has the ability to automatically clean the screen, improving screening efficiency and detection accuracy

Accurate detection: High classification accuracy and accurate detection results. Suitable for particle shape, particle size distribution and various detection

Long service life: Using the standard inspection tools of the state-owned No. 540 Factory, the detection is accurate and the service life is long

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc.

Abrasives, geological survey, metallurgy, pharmacopoeia, chemical building materials, etc.

| Name | Value |

| Dia.(mm) | Φ200 |

| Layer (s) | 5 |

| Frequency (n/min) | 1400 |

| Amplitude (mm) | 1-4 |

| Force (kN) | 3 |

| Chassis level (mm) | ≤0.6 |

| Motor power (kW) | 0.18 |

| Motor speed (r/min) | 1400 |

| Dimensions (mm) | 370(L)×350(W)×650(H) |

| Timing (min) | 1-15 |

The standard test sieve’s basic principle is to convert the rotary motion of the motor into a horizontal, vertical and inclined three-dimensional motion through the eccentric weight mounted on the upper and lower ends of the motor shaft, and then transfer the motion to the screen surface. After the material is forced to produce tumbling, rotating and jumping movements on the screen. With the use of standard sieve frame, it can be used for inspection and measurement of the granular, powder materials’s particle size structure, the amount of liquid solids content and the amount impurity‘s vibration screening, filtration, standard test.

The air flow screen in the air path adopts a closed design. After screening rubber additives, light calcium and other materials, the measured output is 1 ton/㎡/H, the screening efficiency is over 95%, and the dust content in the air is less than 10 mg./m³, which solves the problem of dust flying

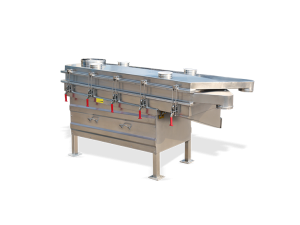

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible