Home / Products / Fine Screening / Positive Pressure Air Flow Sieve

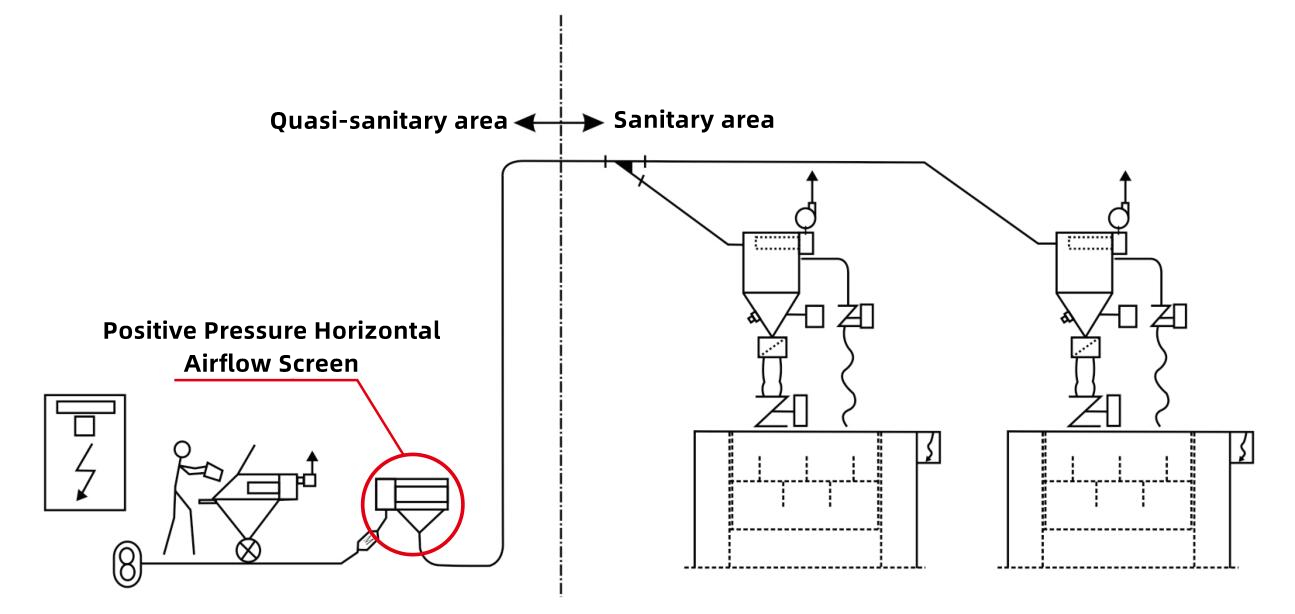

Scope of application: The positive pressure airflow screen is connected in series in the system, saving labor and space, and producing large amounts of fine dust and positive pressure.

Materials: various powders.

Scope of application: The positive pressure airflow screen is connected in series in the system, saving labor and space, and producing large amounts of fine dust and positive pressure.

Materials: various powders.

The working principle of the positive pressure airflow screen:

The material is always under positive pressure during the screening process. The material to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished product quickly passes through the mesh under the action of positive pressure. . The remaining gas is dissipated through the bag dust collector and suction device of the silo.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible