Home / Products / Fine Screening / Linear Vibrating Sieve

Application scope: silicon materials, food industry, pharmaceutical industry, chemical industry, etc.

Application materials: polycrystalline silicon, fused silicon powder, spherical silicon powder, silica, sugar, salt, monosodium glutamate, chicken essence, glucose, amino acids, potassium sorbate, bread crumbs, freeze-dried food, coconut pellets, frozen dumplings, granular pills, Pellets, traditional Chinese medicine pieces, iron powder, aluminum powder, lead powder, copper powder, alloy powder, electrolytic copper powder, refractory materials, steel pellets, alumina, metallurgical powder, sodium bicarbonate (soda ash), etc.

Polycrystalline silicon, fused silicon powder, spherical silicon powder, silica, sugar, salt, monosodium glutamate, chicken essence, glucose, amino acids, potassium sorbate, bread crumbs, freeze-dried food, coconut pellets, frozen dumplings, granular pills, Pellets, traditional Chinese medicine pieces, iron powder, aluminum powder, lead powder, copper powder, alloy powder, electrolytic copper powder, refractory materials, steel pellets, alumina, metallurgical powder, sodium bicarbonate (soda ash), etc.

| Model | Sieving size(mm) | Material size(mm) | Angle(°) | Amplitude(mm) | Layer(s) | Power(kw) |

| SZF520 | 500×2000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(0.4~0.75) |

| SZF525 | 500×2500 | 2×(0.4~0.75) | ||||

| SZF530 | 500×3000 | 2×(0.75~1.1) | ||||

| SZF535 | 500×3500 | 2×(0.75~1.1) | ||||

| SZF1020 | 1000×2000 | 2×(0.75~1.5) | ||||

| SZF1025 | 1000×2500 | 2×(1.1~1.5) | ||||

| SZF1030 | 1000×3000 | 2×(1.5~1.8) | ||||

| SZF1035 | 1000×3500 | 2×(1.5~2.2) | ||||

| SZF1040 | 1000×4000 | 2×(1.5~2.2) | ||||

| SZF1225 | 1200×2500 | 2×(1.5~2.2) | ||||

| SZF1230 | 1200×3000 | 2×(1.8~3) | ||||

| SZF1235 | 1200×3500 | 2×(1.8~3) | ||||

| SZF1530 | 1500×3000 | 2×(2.2~3) | ||||

| SZF1535 | 1500×3500 | 2×(2.2~3) | ||||

| SZF1540 | 1500×4000 | 2×(2.2~4) |

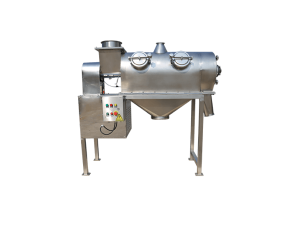

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying

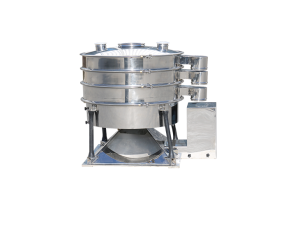

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible