Types of salt

1. According to whether it is edible, it can be divided into industrial salt and edible salt;

2. According to the production process, it can be divided into: sea salt, mineral salt and vacuum salt;

3. According to the use, it can be divided into: industrial salt, feed salt, snow melting salt, health salt, pickling salt and edible salt.

sea salt

It is crystallized in sea water, with a higher iodine content and a lower salt concentration. The production of sea salt in my country generally adopts the solarization method, also called the "spreading method", which uses coastal beaches, builds dams to open up salt fields, and receives tides. The water is raised, attracting seawater to fill the pond, and becomes brine after evaporation by sunlight.

When the evaporation concentration of the brine reaches 25°, sodium chloride is precipitated, which is salt. The process flow of raw salt produced by the Rizhao method is generally: four major procedures: receiving tide, making brine, crystallizing and collecting salt;

mineral salt

Salt mined from salt mines has a higher mineral content and a higher concentration of salt. As the name suggests, mineral salt is salt mined from salt mines, such as rock salt in the desert, Sichuan salt in Sichuan, and mineral salt mined hundreds of meters underground in Poland. Mineral salt is rich in minerals. Mineral salt has been precipitated underground for thousands of years.

In ancient times, industry was underdeveloped and there was little pollution, so the mineral salt has good purity and few impurities. The following methods are mainly used to refine mineral salt:

brine purification → round (flat) pot frying salt → vacuum Evaporation to make salt → Hot-press evaporation to make salt → Hot-press, vacuum and use method to make salt;

Vacuum salt production

The evaporation process uses brine as raw material to produce coarse salt through four-effect evaporation (evaporation tank), advection feeding, downstream salt discharge, and evaporation and crystallization in an externally heated forced circulation evaporator.

The effluent part of the wood leaves is transferred to the nitrate analysis tank after three-stage preheating. The brine is heated up in the nitrate analysis tank and evaporates to nitrate. The mother liquor flows into the flash tank due to the pressure difference, making full use of the waste heat after steam condensation to allow the condensed water to circulate in the flash tank.

Steam flashes out under the pressure difference.

1、granular crystal salt

Production process: Using large grains of sea salt or mineral salt as raw materials, after 1-3 times of mechanical crushing, washing, screening, drying, packaging and other processes, the particles are complete, uniform in size, good in fluidity, and crystal clear;

Crystal salt uses: It has a wide range of uses and is mainly used in bath salts, cosmetics production, skin care products, shower gel, etc.

2、hot compress salt

Hot compress salt production process: It is usually made through a series of processes such as seawater evaporation, filtration, and drying. Use of hot compress salt: commonly used to make hot compress salt packs and physical therapy products. Hot salt compresses will generate heat after electric heating.

This heat can promote the resolution of inflammation, relieve pain, reduce congestion in deep tissues, and keep warm the human body. It plays a huge role and impact on people's physical health.

3、Snowmelt salt

Purpose of snow-melting salt: Snow-melting salt melts the snow on the road by lowering the melting temperature of ice and snow, which facilitates road dredging. The effect is obvious where it is sown.

It is an inorganic snow-melting salt with "chlorine salt" as the main component, such as sodium chloride, calcium chloride, Magnesium chloride, potassium chloride, etc. are commonly known as 'ice salts'

4、feed salt

Purpose of feed salt: In the animal body, chloride ions and sodium ions mainly exist in body fluids and soft tissues. They maintain osmotic pressure, regulate acid-base balance, and control water metabolism. They are mineral elements necessary for the normal growth and development of animals. Chlorination Sodium has a salty taste, which can improve the palatability of feed. Enhance appetite, help digestion and absorption of nutrients, and improve feed utilization. Lack of salt or insufficient salt content in feed can cause loss of appetite, digestive disorders, and pica in livestock and poultry. Therefore, the feed additive sodium chloride is an important mineral in livestock and poultry feed and an essential substance for the life-sustaining activities of livestock and poultry.

5、curing salt

Purposes of pickling salt: Mainly used for pickling meat and pickles. The main raw materials and specifications are sea and lake salt.

Pickling salt production method and process flow: the raw material salt is washed, dried, screened, and selected to obtain the finished pickling salt.

6、Fertilizer additives

Fertilizer additive uses: Chemicals used to improve fertilizer performance, promote fertilizer efficacy, decompose residual pesticides, nitrates and improve the soil environment.

7、refined salt

The sodium chloride content in refined salt is high, with few impurities, less refined preparations are consumed, and there is less salt sludge. The refined brine is of good quality, which is beneficial to production. It is also increasingly valued by chlor-alkali enterprises, and the raw salt of the chlor-alkali industry is gradually being converted into refined salt.

There are certain differences between refined salt, powdered salt, and sun-dried salt. The production process involves more crushing, washing, recrystallization and other processes than ordinary pickling salt, so the price will be higher.

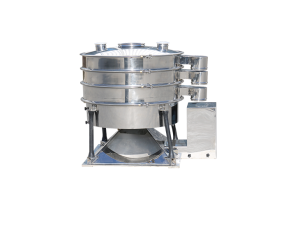

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

When two vibrating motors installed longitudinally on the screen body run relative to each other, the horizontal excitation forces generated by them cancel each other out due to the relative operation of the motors, and the longitudinal excitation force is transmitted to the entire screen box through the vibration transmission body. The screen surface is vibrated, so that the materials on the screen surface are subject to the excitation force and jump on the screen surface in the direction of the discharged product. The materials smaller than the screen hole fall to the lower layer through the screen hole, and then jump from The discharge port flows out. Due to the reasonable screening process, after the materials are classified by the vibrating screen, several materials with different particle sizes can be obtained to complete the material classification operation.

Probability screen is a kind of sieve machinery which can make use of the principle of probabilistic screening. The sieve theory points out that, the stranded time of each object in its interior is opposite to its weight in the work. Through the actual experiment, particle size is much smaller than the hole diameter, it can quickly pass the screen surface, the more close to the hole diameter, the longer the stranded time, if the diameter of the two sides are close, the stranded time of the material is the longest, popular speaking, large particles stay time is long , small particles stay time is short.