Ceramic powder introduction

The so-called ceramic powder is a powdery substance in which all the raw materials are uniformly mixed and then calcined (also called calcination, pre-synthesis) when preparing the ceramic. The chemical reaction between the raw materials of the ceramic is not carried out in a molten state, but it is achieved by diffusion between atoms (or ions) at a temperature lower than the melting point, that is, a solid phase reaction, so The ceramic powder obtained by calcination (pre-synthesis) is already a pure phase crystalline material.

Ceramic process

First, kaolin, ceramic powder and other raw materials are ground by a ball mill according to the proportion of ceramic formula, and then sieved through the first vibrating screen. At this time, the mesh number is about 30-50 mesh. The sieved raw material enters the slurry tank, and then the water is thoroughly mixed by the mixer, and the discharged slurry is sieved through second vibrating sieve. At this time, the mesh number is between 80 and 325 mesh. The number of meshes depends on the requirements of the product. The resulting slurry is then placed in a ceramic kiln for drying into ceramic granules, which are then formed by a press and then calcined into a kiln. After polishing, uranium is required for uranium bricks. Uranium is filtered by a vibrating filter during uranium application.

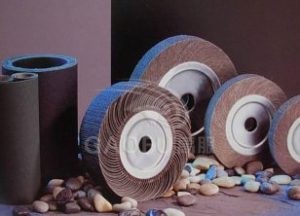

Abrasive introduction

Abrasives are sharp, hard materials that grind softer material surfaces. Abrasives with natural abrasive and artificial abrasive two broad categories. According to the hardness of the super-hard abrasive and general extra-abrasive two categories. Abrasives range from softer household detergents, gem abrasives to the hardest material diamonds. Abrasive materials are indispensable for the manufacture of every precision product. Many natural abrasives have been replaced by artificial abrasives. In addition to diamonds, natural abrasive properties are not stable, but still its use value. Diamond is the hardest abrasive, origin South Africa, accounting for 95% of the world’s total output, the rest of Brazil, Australia, Guyana and Venezuela and other places. Industrial diamond from white to black ranging from crushed grinding wheel, belt, polishing wheel and grinding powder.

Dehydrated vegetables: also known as cabbage, is a kind of dried vegetable which is made of fresh vegetables after washing, drying and so on. After removing most of the water in vegetables, the original color and nutrition of vegetables are basically kept unchanged. It is easy to store and transport, and can effectively regulate the vegetable production in the light season. When eaten, it is soaked in clean water. It can recover and preserve the original color, nutrition and flavor of the vegetables.

Which limestone needs screening?

1. For power plant desulphurization, for example: limestone manufacturers, broken material has a part of super-diameter particles;

2. recovery of ground stone powder.

The practical significance of power plant slag separation and the process flow and design scheme of slag dewatering, the successful case of slag dewatering process in the application of self-supplied power plant of Xinlianxin Fertilizer Company, the slag dewatering sieve has achieved zero discharge of slag water after production, and achieved energy saving effect. And economic and social benefits.

Material properties and characteristics:

water content when high and low, coal quality is good and bad, coal contains gangue

material crushing difficult problem: (such as sticky plugging, large amount of treatment, dust serious)

1. High moisture content of coal, easy to stick to block equipment during crushing;

2. Coal contains gangue, to hammer head or tooth plate wear more serious;

3. The dust is heavy.

1, flotation tailings of coking coal preparation plant

2, slime is produced by coal-water mixture

3, the slime from mine drainage and gangue mountain watering washed down

Characteristics of slime

1, fine grain size, more particle content, especially less than 200 mesh particles accounted for about 70% to 90%.

2, strong water holding capacity, high moisture content. The slime water content is generally more than 30% after sludge filtered by the disc vacuum filter. Folding belt filter dehydrated slime water content in 26% to 29%; the filter press dehydrated slime water content in 20% to 24%.

3, Ash content is high, low calorific value. The slime can be divided into three categories according to the ash and calorific value: low ash coal ash is 20% to 32%, calorific value of 12.5 ~ 20MJ / kg; middle ash coal ash is 30% to 55% , calorific value of 8.4 ~ 12.5MJ / kg; high ash coal ash is > 55%, calorific value of 3.5 ~ 6.3MJ / kg.

4, More sticky. As the slime generally contains more clay minerals, coupled with high moisture content, particle size composition is fine, so most of the slime viscosity, and some also have a certain mobility. Due to these characteristics, it is difficult to pile, store and transport slime. Especially in the stockpile, its shape is very unstable, water is lost, dry that is flying. The result is not only a waste of valuable coal resources, but also caused serious environmental pollution, and sometimes even constrained the normal production of coal preparation plant, a coal preparation plant a more difficult problem.

Dry mortar introduction

Dry mortar refers to a granular or powdery form of dry-sieged aggregate (such as quartz sand), inorganic cementitious materials (such as cement) and additives (such as polymers), which are physically mixed in a certain proportion. It can be transported to the construction site in bag or bulk form. After mixing with water, the material can be used directly. Also known as mortar dry powder, dry mix, dry mix, some construction adhesives also fall into this category. Dry mortar plays a role in bonding, lining, protection and decoration in a thin layer in the construction industry. Construction and decoration engineering applications are extremely extensive.