Home / Solutions / Pharmaceutical industry solutions / Chinese medicine pill

Chinese medicine pill is the traditional Chinese medicine preparation of the traditional dosage forms, the production of the Chinese herbal medicine by crushing, sieve, sterilization, ingredients, mixing, lump, pills, drying, packaging and other processes made, due to the requirements of the product more and more the higher the post-dry pills need to be sieved again, evenly classified, packaged in the same size and price will expensive.

Chinese medicine pill is the traditional Chinese medicine preparation of the traditional dosage forms, the production of the Chinese herbal medicine by crushing, sieve, sterilization, ingredients, mixing, lump, pills, drying, packaging and other processes made, due to the requirements of the product more and more the higher the post-dry pills need to be sieved again, evenly classified, packaged in the same size and price will expensive.

Remove the spheronizer after the pill like a conjoined twins, the size of the pill to ensure that the pill is uniform and complete.

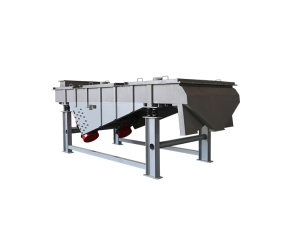

GFZX granule pill vibrating screen is a Xinxiang Gaofu company engaged in medical screening equipment design and manufacture of years of experience wisdom crystallization, the use of sieve machine box body by the motor shaft rotation traction to produce the principle of circular motion, pellet material rolling on the screen surface, Less than the mesh of the pellets through the hole, the larger than the mesh particles directly discharged particles. The entire process of material balance and smooth rolling, almost no damage, and even wet pills screening can also play the same effect.

Wet and dry pills, granules, a multi-purpose machine

Efficient removal of dripping pills, honey pill, granule granules, filling capsules and other granular materials within the slag and fine powder

Do not blog the screen, to ensure that sieve production

According to the special nature of various materials, product the special screens, do not blog screen, to ensure the sieve production increased.

Dry pills are not damaged, wet pills are not deformed

Unique amplitude and vibration frequency design, so that dry pills are not broken, wet pills are not deformed to ensure that the particles are uniform and complete

1. With the feeder with the use of materials even into the sieve, the material sieve more accurate.

2. According to the specificity of each material, the produce of special screens, do not block the screen, sieve production increased.

3. The unique amplitude and vibration frequency design, so that dry pills are not broken, wet pills are not deformed, the powder particles more thoroughly.

4. Pellet pill vibrating screen low energy consumption, high yield, easy operation, good cleaning, fully enclosed structure, automatic discharge, suitable for assembly line production.

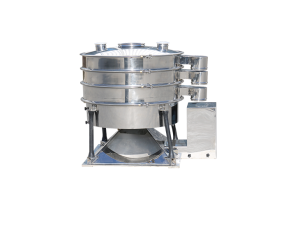

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

It has unique effects on the screening and classification of powdery and granular materials.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)