Home / Solutions / Chemical industry solutions / Zirconia balls

Common zirconia balls include 95 zirconium beads and 65 zirconium beads, which are generally used for grinding in the food, pharmaceutical and electronic industries. The particle sizes of zirconium beads used in different industries and different grinding machines are also different.

If zirconium beads of different particle sizes are mixed together during production and you want to quickly separate zirconium beads of different particle sizes, what kind of screening equipment should be selected?

Common zirconia balls include 95 zirconium beads and 65 zirconium beads, which are generally used for grinding in the food, pharmaceutical and electronic industries.

The particle sizes of zirconium beads used in different industries and different grinding machines are also different.

If zirconium beads of different particle sizes are mixed together during production and you want to quickly separate zirconium beads of different particle sizes, what kind of screening equipment should be selected?

1. The screen has high tension and high aperture accuracy. Long-term use will not cause uneven aperture sizes, so the separated zirconium beads of different particle sizes have high accuracy.

It makes enterprises more competitive when selling zirconium beads and is also convenient for users;

2. The screen adopts a sub-mesh structure, and the sub-net is supported by the main mesh to increase the service life of the sub-net. This design also facilitates screen replacement, which can be completed in 3-5 minutes, reducing workers’ workload and improving work efficiency;

3. It can work continuously, automatically discharge materials, and add soft connections at the inlet and outlet, suitable for assembly line operations;

4. The discharge port can be rotated 360°, making it easy for enterprises to connect upstream and downstream equipment when using the rotary vibrating screen.

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

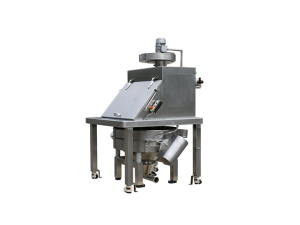

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line