Home / Solutions / Food industry solutions / Soybean milk

Realize the separation of pulp and residue, reduce the residue content in soy milk, improve the fineness of soy milk, and enhance the taste; the equipment is suitable for 24-hour production lines, has high equipment stability and good sealing performance, and is especially suitable for slurry screening.

Before soy milk is ground, soybeans that have been soaked in water are ground through a refiner. The slurry contains soy milk and a large amount of bean dregs. Although the outlet of the refiner is equipped with a filter, which can roughly separate the soy milk and bean dregs, it still cannot meet the needs of our daily life. In order to make the soy milk or soy products more delicious, a filter screen is used to make tofu. The mesh number of the sieve is 100-200, and the sieve mesh of 200-300 should be used for making tofu skin and dried tofu.

Introduction of soybean milk

Soybean milk is a favorite drink of the Chinese people and is also a nutritious food for all ages. It enjoys the reputation of "plant milk" in Europe and the United States. Soy milk is rich in vegetable protein and phospholipids, also contains vitamin B1.B2 and niacin. In addition, soybean milk also contains iron, calcium and other minerals, especially its contained calcium, is very suitable for a variety of groups, including the elderly, adults, adolescents, children and so on. Soybean Milk, traditional Chinese drink, The earliest soybean milk was produced by the king of huainan An Liu. Soybean with water after the bubble up, filtered, boiled. Soybean milk is rich in nutrition and easy to absorb.Unlike milk from the west, soybean milk is a very special Chinese food, widely popular in the Chinese region.The benefits of soy milk frequently are the following: a strong body.Prevention of diabetes prevention and control of high blood pressure to prevent senile stagnation, AIDS, constipation, obesity, etc.

Soy products like tofu, bean curd, bean curd stick, etc. Products in the process of production of pulping machine grinding out soya-bean milk contains a certain amount of bean dregs, if not cleared, will seriously affect the product quality of bean products taste, In soybean processing, most of the enterprises in the process of removing okara use the most primitive filtering method of artificial use of filter cloth to shake. At a time when labor cost is very high, the operation is labor-intensive and the work efficiency is low, especially in summer soybean production workshop temperature is high, the workers had to work in high temperature operation, it’s very dangerous and the output does not come, according to the characteristics of soybean milk residue improve milk filter suitable for soybean milk filter sieve.

Purposes of Soybean milk screening and filtration

To achieve residue separation, reduce the amount of slag in the milk to enhance post-production products.

Soybean milk before grinding into the blisters after the soybeans grind out through the refiner, there are milk in the slurry also includes a large amount of okara. Although the discharge port of the refiner is provided with a filter, which can roughly separate the soybean milk and the bean residue, but still can not meet the needs of our daily life, In order to make soybean milk or soy products made more delicious, making use of tofu filter sieve mesh in the 100-200 mesh, and the production of bean curd and dried bean curd should be used 200-300 mesh.

Production process technology

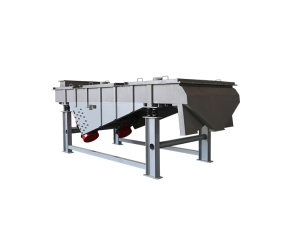

Slurry separator / colloid mill - boiled pulp - pump, pipe - vibrating sieve

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

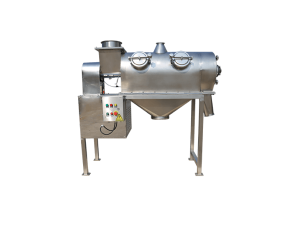

It has unique effects on the screening and classification of powdery and granular materials.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying