Home / Solutions / Chemical industry solutions / Positive and negative materials

Cathode: Lithium cobalt oxide, Lithium iron phosphate, Lithium manganese oxide, Ternary material (Lithium nickel cobalt manganese oxide)

Negative: Carbon (artificial graphite, natural graphite, mesocarbon microbeads), lithium titanate

Cathode: Lithium cobalt oxide, Lithium iron phosphate, Lithium manganese oxide, Ternary material (Lithium nickel cobalt manganese oxide)

Negative: Carbon (artificial graphite, natural graphite, mesocarbon microbeads), lithium titanate

Positive electrode: lithium cobalt oxide as an example; cobalt tetroxide, conductive agent (acetylene black), binder as raw material, crushing (jet mill) - the proportion of raw materials weighed (weighing meter) - mixing(Mixer)-sintering (sintering furnace) - crushing (jet mill) - screening (ultrasonic) - iron removal (PM) - packaging (During which include vacuum feeding or vibration feeding and dust removal equipment)

Negative: Take natural graphite as an example: Graphite - Crushing - Mixing - High Temperature Degreasing (Strip Furnace) - Chemical Purification - Drying - Sieving - Mixing - Coating Carbonization - Magnet(Magnetic Separator) - Sieving(Ultrasonic)-package

1. Production: Some factory because of process factors, poor material flow, high viscosity and low capacity;

2. Maintenance rate: from six months to one year, the ultrasound probe and the line and the power will appear maintenance point;

3. Screen Life: Some factory reflect the screen life is short;

4. Pollutants: iron and copper metal will pollute the raw materials, resulting in reduced battery capacity;

5. Over-size mesh: over the mesh aperture material appears in the down screen, increasing the probability of diaphragm damage.

1. Production: Tianjin Bamo cobalt lithium test, the output of similar models of our company slightly higher than our peers;

2. Maintenance rate: Our ultrasonic probe is not easy to damage, the line have protection tube for secondary protection;

3. Screen Life: Mother-son ultrasonic frame can significantly improve the screen life;

4. Superfine material pass mesh: By reducing the ultrasonic vibration frequency and reducing the exciting force of the screen, the result is 7 times less than the conventional screen superfine material pass mesh;

5. After-sales service is guaranteed.

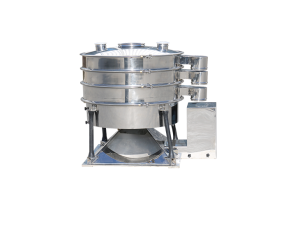

Gaofu combines ultrasonic and vibrating screens to solve the problem of difficult screening of highly adsorbent materials.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.