Home / Products / Fine Screening / Granular Square Sieve

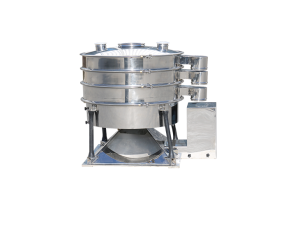

Detailed classification: According to the particularity of each material, special screens are formulated to prevent clogging, blocking and jamming, and the screening output is increased

High efficiency: The unique amplitude and frequency design method prevents dry pills from breaking, wet pills from deforming, and the particles and powders are separated more thoroughly

Low energy and high output: Low energy consumption, high output, easy to operate, easy to clean, fully enclosed structure, automatic discharge, suitable for assembly line production

Food industry, pharmaceutical industry, chemical industry, other industries, etc.

Screening of granular materials in food, pharmaceutical and biological industries such as freeze-dried food (apple slices, strawberries, grapes, dried fruits and vegetables), bread crumbs, coconut granules, granules, dripping pills, honey pills, filled capsules and other industries.

| Model | Dimensions(mm) | Material Size(mm) | Angle(°) | Amplitude (mm) | Layer(s) | Power(kW) |

| GFP-515 | 500×1500 | 0.25~15 | 0°~7° | 1~8 | 1~3 | 2x(0.15~0.25) |

| GFP-520 | 500×2000 | 2x(0.15~0.25) | ||||

| GFP-615 | 600×1500 | 2x(0.15~0.25) | ||||

| GFP-620 | 600×2000 | 2x(0.25~0.4) | ||||

| GFP-820 | 800×2000 | 2x(0.4~1.1) | ||||

| GFP-825 | 800×2500 | 2x(0.75~1.1) |

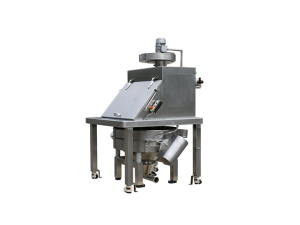

GFP series granular square screen is a quick-detachable linear vibrating screen designed and manufactured by Gaofu Company for the high-end requirements of food, pharmaceutical and other industries. It can effectively remove agglomerates and fine powder caused by the production process to ensure uniform and complete particles. It has the characteristics of low energy consumption, high output, easy operation, easy cleaning, fully enclosed structure, automatic discharge, and is suitable for 24-hour assembly line production.

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible