Home / Solutions / Chemical industry / Brake pad premix

Car brake pads, also known as car brake pads, refer to friction materials fixed on brake drums or brake discs that rotate with the wheels. The friction pads and pads bear external pressure, producing friction and achieving the purpose of vehicle deceleration.

Car brake pads are generally composed of steel plates, adhesive insulation layers and friction blocks. The steel plates must be painted to prevent rust. During the coating process, an SMT-4 furnace temperature tracker is used to detect the temperature distribution during the coating process to ensure quality. Brake pad premix: barite, barium sulfate, iron oxide red, resin, etc.

Car brake pads, also known as car brake pads, refer to friction materials fixed on brake drums or brake discs that rotate with the wheels. The friction pads and pads bear external pressure, producing friction and achieving the purpose of vehicle deceleration.

Car brake pads are generally composed of steel plates, adhesive insulation layers and friction blocks. The steel plates must be painted to prevent rust. During the coating process, an SMT-4 furnace temperature tracker is used to detect the temperature distribution during the coating process to ensure quality. Brake pad premix: barite, barium sulfate, iron oxide red, resin, etc.

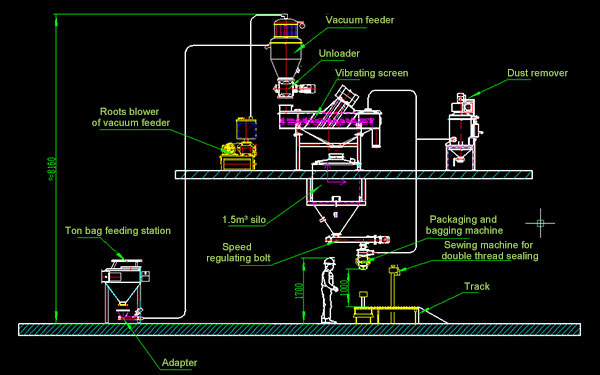

Original production process: tons of packaging raw materials --- manual feeding --- belts --- screening machine --- manual material receiving

The customer made a self-made screening machine with small output and poor environmental protection, and employees did not want to work on it.

The dust-free feeding and screening system is an integrated solution integrating loading, conveying, feeding, screening and dust removal, with high production efficiency and environmental friendliness.

Current status before rectification

Solution after rectification

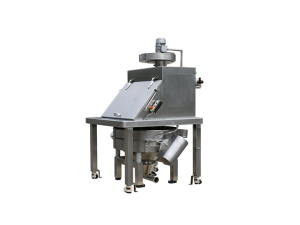

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

When two vibrating motors installed longitudinally on the screen body run relative to each other, the horizontal excitation forces generated by them cancel each other out due to the relative operation of the motors, and the longitudinal excitation force is transmitted to the entire screen box through the vibration transmission body. The screen surface is vibrated, so that the materials on the screen surface are subject to the excitation force and jump on the screen surface in the direction of the discharged product. The materials smaller than the screen hole fall to the lower layer through the screen hole, and then jump from The discharge port flows out. Due to the reasonable screening process, after the materials are classified by the vibrating screen, several materials with different particle sizes can be obtained to complete the material classification operation.

It is suitable for many industries such as medicine, foodstuff, chemical industry, metallurgy and building material, aiming at the confinement transportation of various powder materials, improving the cleanliness of materials, which can meet the diversified transportation needs of different customers.