The small food flour supply system uses two flour or starch powder supply systems at the same time. It is mainly used for snack foods. The dough mixer automatically quantifies the dough during mixing. The quantification does not take up the dough mixing time, and a quantification cycle is completed in 3 minutes. , the blanking time is 10–20 seconds, and the quantification is accurate.

The small food flour supply system uses two flour or starch powder supply systems at the same time. It is mainly used for snack foods. The dough mixer automatically quantifies the dough during mixing. The quantification does not take up the dough mixing time, and a quantification cycle is completed in 3 minutes. , the blanking time is 10–20 seconds, and the quantification is accurate.

The small food flour supply system uses two flour or starch powder supply systems at the same time. It is mainly used for snack foods. The dough mixer automatically quantifies the dough during mixing. The quantification does not take up the dough mixing time, and a quantification cycle is completed in 3 minutes. , the blanking time is 10–20 seconds, and the quantification is accurate.

The small food flour supply system uses two flour or starch powder supply systems at the same time. It is mainly used for snack foods. The dough mixer automatically quantifies the dough during mixing. The quantification does not take up the dough mixing time, and a quantification cycle is completed in 3 minutes. , the blanking time is 10–20 seconds, and the quantification is accurate.

The small food flour supply system uses two flour or starch powder supply systems at the same time. It is mainly used for snack foods. The dough mixer automatically quantifies the dough during mixing. The quantification does not take up the dough mixing time, and a quantification cycle is completed in 3 minutes. , the blanking time is 10–20 seconds, and the quantification is accurate.

The small food flour supply system uses two flour or starch powder supply systems at the same time. It is mainly used for snack foods. The dough mixer automatically quantifies the dough during mixing. The quantification does not take up the dough mixing time, and a quantification cycle is completed in 3 minutes. , the blanking time is 10–20 seconds, and the quantification is accurate.

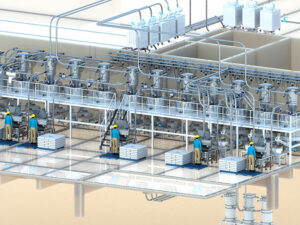

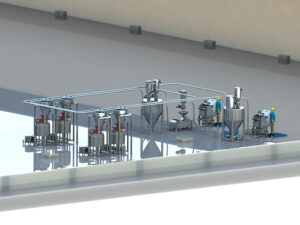

Use dust-free feeding and vacuum feeder to lift sesame and powdered sugar into the buffer bin, and then lift into the temporary storage bin after weighing. The flour enters the buffer bin and the online weighing bin under positive pressure to achieve sugar weighing 75 kg and 25 kg of sesame into the mixing tank and mix for 5 minutes, then put in 150kg flour, and repeat the operation for 3 minutes.

The system consists of a feeding station, a buffer storage bin, a vacuum feeder, a pulse dust collector, a weighing bin, etc.

The system consists of a bag feeding station, a buffer storage bin, a distribution valve, a weighing bin, and a dough mixer