The new tailings dry-cleaning process came into being in the following situations: 1, the national policy requirements; 2, tailings warehouse to extend the service life; 3, the need to re-use the closed tailings; 4,need to use dry slag for filling pit, land forming; 5, severe seepage tailings reservoir; 6, severe water shortage area.

Gaofu machinery is made for each tailings dry process technology are efficient and energy-efficient minimum operating costs of the process. Drying of the slag after filling the pit, field, dam, manufacturing building materials, the filtrate to achieve the requirements of recycling,return to continue to use the production, energy and water conservation effect is significant.

The new tailings dry-cleaning process came into being in the following situations: 1, the national policy requirements; 2, tailings warehouse to extend the service life; 3, the need to re-use the closed tailings; 4,need to use dry slag for filling pit, land forming; 5, severe seepage tailings reservoir; 6, severe water shortage area.

Gold tailings, silver tailings, iron tailings, tailings, lead tailings, zinc tailings, molybdenum tailings, chrome tailings, manganese tailings, nickel tailings, tin tailings, tungsten tailings, Mine, vanadium tailings, barite tailings, calcite tailings, fluorite tailings, potassium long stone tailings, graphite tailings, zircon tailings and so on

1, adopt tailings dry row technology to solve the traditional tailings emissions, resulting in environmental pollution, dam risk and occupation of a large number of land problems;

2,after the tailings dehydration, dry emissions, it can save the traditional tailings of the construction costs and conventional maintenance costs, but also make full use of gravity backwater, play a role in energy efficiency;

3, Dry row tailings can be changed waste to treasure, comprehensive utilization, such as filling gob, can eliminate security risks, restore land reclamation, save environmental management funds to protect the geological environment, to achieve waste replacement.

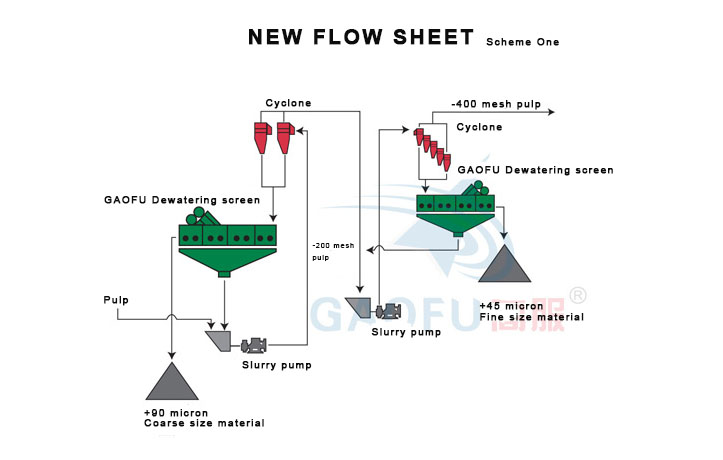

The following is a comparison of two kinds of tailings dry scheduling, mainly for coarse sand tailings can be directly into the tailings dewater screen, dry row treatment and backwater utilization, so as to avoid mining industry in tailings dry row processing, Investment in equipment produce high operating costs, resulting in unnecessary investment. Taking the 3000t / d iron tailings dry row as an example, this paper analyzes the advantages and disadvantages of the two tailings drying methods and hopes to help the mining industry who needs tailings dry processing.

| Case | Case situation | Return water | Coarse sand return |

| Case number one | An iron ore mill belongs to the old line reconstruction project. The 3000t / d iron tailings is produced 24 hours a day, with a tailing concentration of 20%. coarse than 100mesh percentage is around 70%, More than 85% of the dry weight after dewater screen, dry tailings slag water <15%, bottom flow through the settlement can be back to water use, a small part of the tailings into the tailings reservoir. More than 30% water save after screening, increase tailings reservoir capacity of 30% or more, and can protect the slurry pump. | daily processing tailings (water and tailings) 15000t / d, after the dewater screen tailings and water were taken away 5000t / d, leaving 10,000 tons of water, the original tailings can be recycled 50%, according to the present Recyclable 80%, 30% more recycling, tailings dewater screen can save water: 15000-5000 * (0.8-0.5) = 3000 tons / day, according to the water price of 0.12 usd / ton, 3000 * 0.12 = 360usd / day , Work 300 days a year, 360 * 300 = 108000usd, a year can save 108000usd of water resources. | daily discharge of coarse sand 2550 tons, 1.5usd per ton profit, 300 days a year work, 2550 * 1.5 * 300 = 1147500usd, 1147500usd annual return of coarse sand. The 3000t / d iron tailings using tailings sieve only invest about 181818usd. |

| Case two | Vanadium ore plant, 500t / d vanadium tailings, the concentration of 25%, particle size roughly 100% with about 70%, with dry sieve can extract more than 95% of dry ore, tailings after the dry screen water content is less than 20 %. Tailings dry tailings tailings for building materials, tailings resources reuse; underflow can be directly back to water use, completely without tailings storehouse. | treatment tailings capacity (water and tailings) 2000t / d, after the dry screen of tailings and water taken away 900t / d, the remaining 1100 tons of water, according to the price of 0.12usd / ton, 1100 * 0.12= 132usd, 300 days a year work, 132 * 300 = 39600usd, a year can save 39600usd of water resources. | 475 tons per day of dry coarse sand discharge, according to 1.5usd per ton profit, work 300 days a year, 475 * 1.5 * 300 =213750usd, annual grit return 213750usd.500t / d vanadium tailings using tailings sieve investment about 75757usd. |

| Comparison of projects | The main equipment | The applicable particle size | Power(KW) | Wear parts | Investment amount (usd) | Production costs (usd) | advantage |

| preferred program (new technology) | tailings dewater screen 2 sets | ≤200 mesh is more than 50% | ≈44KW | sieve plate more than 7 months | ≈ 75757usd | ≈ 0.04usd / ton | 1, small footprint. 2, investment time is short, can be used after arrive in site. 3, tailings sand can also be graded, the size can be reused separately. 4, reduce the dosage, automatic delivery. 5, environmental protection in line with national emission requirements. |

| the traditional program(Old craft) | Concentration pool 1 + filter 4 sets | 50 mesh -500 mesh size | ≈600KW | filter cloth 1-3 months | ≈ 1363636usd | ≈ 0.73usd / ton | can be directly back to water use |

Dewatering screen adopt dual-electrode self-synchronization technology, universal eccentric block, adjustable amplitude vibrator. The machine is combined mainly by the screen box, exciter, support system and motor. The two mutually independent vibrators are respectively driven by the tape coupling to do synchronous reverse operation. The centrifugal force generated by two eccentric masses is superposed along the vibration direction and reversely counteracted, thereby forming a single vibration force along the vibration direction, making the screen box reciprocating linear motion.

Dewatering screen, also known as high-frequency dewatering screen, changing the water surface tension of pulp through the exciting force, pulp water through the screen to become the undersize material, and fine material is blocked by the screen to form the filter layer by the vibration of the forward movement of discharge. Dewatering screen is mainly used for detailings dewatering in the mineral processing industry, coal slurry dehydration of coal preparation plant, washed quartz sand dewatering and ceramic slurry dehydration, and wet and dry classification, dehydration, removal and mud removal of medium and fine granular materials in industrial sectors such as electric power, sugar making and salt making.