Lead trioxide (chemical formula Pb3O4), commonly known as red lead and lead lead, has a relative molecular mass of 685.60. National standard number: 61507, CAS number: 1314-41-6. Mainly used as anti-rust pigment, oxidant for organic synthesis, and battery powder making. It is a bright orange-red powder or solid block. It is insoluble in water, but soluble in hot alkali, dilute nitric acid, acetic acid, and hydrochloric acid. It is a toxic chemical.

Lead trioxide (chemical formula PB3 O 4), commonly known as red Dan, lead Dan, relative molecular weight 685.60. National Standard No.: 61507 / CAS No.: 1314-41-6. Mainly used as antirust pigment, organic synthetic oxidant, battery powder making. It is a fresh orange powder or block solid, it is insoluble in water, but soluble in hot lye, rare nitric acid, acetic acid, hydrochloric acid. It is a toxic chemical.

To remove particles and fibrous materials that are not thoroughly crushed; remove large caking impurities.

After heating and melting of lead, small lead particles are prepared by ball milling and grinding at about 20 ℃ and then calcined at 300 ℃ and then oxidized at 500 ℃ to produce lead trioxide.

1.Lead trioxide is toxic, inhaled in the body will cause respiratory poisoning, when serious directly threaten personal safety, so in the recommended equipment and equipment layout must consider the sealing of equipment itself and the sealing of the upper and lower pipeline connection;

2.Location of equipment: generally speaking, lead trioxide is transported directly to the sieve through a screw feeder.

3.The material after screening is transported directly to the packaging machine through the airflow conveyor under negative pressure, so if the old line is reformed, the height of the equipment must be considered.

4.Maneuverability of the equipment: because lead trioxide itself is very abrasive, the service life of screening is very short, and the average life span is about 4-7 days. Therefore, the convenience of the ring network and the operability of the workers must be considered in the recommended equipment.

Because the output is larger and the sieve occupies less, two models are generally recommended:

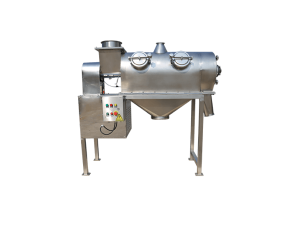

1.Type WSA-30-100-304 horizontal airflow screen:

Output of equipment: 3-4 tons per hour

Screening problem: when horizontal airflow screen is selected, stainless steel screen is usually chosen, but the working principle of airflow screen is that 960 r-1100 rpm high speed rotation produces centrifugal force and whirlwind propulsion force, thus forcing the material to jet through the screen. The material that passes through the net has the finished product fine material mouth to exclude, cannot cross the net material, especially the fibrous thing will adhere to the screen because of the static electricity often time, on the one hand affects the material passing the net rate, thus increases the equipment and the screen net load, As a result of the material grinding large, so the screen will appear in 3-4 days of rotten mesh phenomenon.

The following is the status of the use of the on-site cage by the customer:

2. SZS-1500 type 1S-304 double vibration source straight row screen;

Output of equipment: 4 tons per hour;

Screening problem: because the screen mesh is replaced frequently, it is generally recommended that the sub-mother mesh frame, but the sub-mother mesh frame is heavy and the mesh holes in the screen mesh are thicker at 14 mesh, so it is more troublesome to replace the mesh frame and screen mesh than the airflow screen.

Zhejiang Jiangsen Autocontrol Battery Co., Ltd.

Responsible Editor:Xinxiang Gaofu Machinery Co., Ltd.

Please indicate the source: https://www.gaoful.com

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line