Home / Solutions / Chemical industry / Feed additives – Sulfuric acid

A small amount or trace of substance added during feed production and processing and use of feed additives is seldom used in feed, but it has a significant effect. Feed additives are essential raw materials for the modern feed industry. They have obvious effect on strengthening the nutritional value of basic feed, improving animal production performance, ensuring animal health, saving feed cost and improving animal product quality.

A small amount or trace of substance added during feed production and processing and use of feed additives is seldom used in feed, but it has a significant effect. Feed additives are essential raw materials for the modern feed industry. They have obvious effect on strengthening the nutritional value of basic feed, improving animal production performance, ensuring animal health, saving feed cost and improving animal product quality.

Additives: amino acids, vitamins, trace elements, enzyme preparations, antioxidants.

race elements: Mainly copper, zinc, iron, manganese, iodine, cobalt, molybdenum, selenium, chromium and other elements. These elements have a comprehensive function of regulating the body's metabolism, promoting growth and development, improving carcass quality, enhancing resistance to disease and improving feed conversion rate, such as ferrous sulfate, zinc sulfate, manganese sulfate, calcium carbonate, iodine iodide, sodium chloride etc.

Sulfuric acid feed additives are usually crystals, which are sieving through drying, so the purpose of screening is to remove the crystals or blocky crystals that are adherent in the drying process.

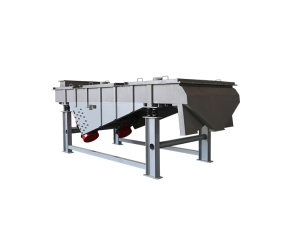

Mesh size: 10-60mesh;

Capacity: 5000-10000 kg/h

Suitable machine: S49-1500/S49-1200/S49-1000/S49-800 one layer, two layer or three layer;

Machine’s material: Because of the slight corrosion of the material, most customers choose the contact material as SUS304 stainless steel, and some customers also choose Q235A carbon steel to save cost.

Type of screen frame: Z model screen frame, because the different types of animals, the needs of buyers are not the same, so a wide range of such additives, generally in order to change the network convenience, it is recommended that customers choose the type of Z model;

Material of Gasket: Rubber gasket

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

It has unique effects on the screening and classification of powdery and granular materials.