Home / Solutions / Mining Industry Solutions / Sludge dewatering system

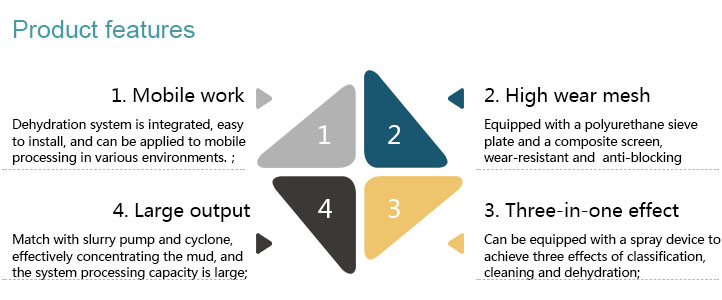

Sludge dewatering system includes slurry pump、dewater screen、 Cyclone and power supply system. Single set of systems can achieve grading、 leaching、dehydration,it can effectively reduce investment costs、operating costs.

Sludge dewatering system includes slurry pump、dewater screen、 Cyclone and power supply system. Single set of systems can achieve grading、 leaching、dehydration,it can effectively reduce investment costs、operating costs.

Pipe network sludge dewatering、river lake dredging、sewage pretreatment、Slag dewatering, mud treatment, construction mud, drilling mud dewatering, biochemical pool sewage treatment.

Ganfu sludge dewatering system use special slurry pump to pump sewage to the dewater screen mesh surface , through the large-diameter polyurethane sieve, screen out the large pieces of gravel and others, the mud under the sieve through the cyclone high concentration, is transport to the fine screen surface, make the most of the fine sand dehydration dry row. The system can be added sprinkler device, to achieve the three effects of cleaning, grading, dehydration.

Pipe network sludge, also known as channel sludge, refers to the sediment in the urban drainage pipes , including branches, plastic bags, packaging (bottles), fiber, stones, sediment and other ingredients. Excessive pipe network sludge formation of silting, not only caused poor drainage pipes, to form urban waterlogging. but also will bring the smelly swage overflowing, mosquito breeding and a series of environmental problems.

According to this circumstance, Gaofu machinery push out sludge dewatering system, the system have supporting cyclone, both grading、 dehydration function, it can be done in a smaller space (container compartment), while dealing with large pieces of garbage and fine particles. Dry sludge discharged from the machine, the water content is small, no leakage during transit, reducing secondary pollution.

The system integration is high, installed in the container frame, vehicle dredging adapt to the urban pipe network segmentation processing, walk and stop freely.

Pile drilling mud refers to the road, drilling and other projects, A large amount of high concertration of mud produced by the rinse bit. Large mud flow, bad storage and return water treatment, and easy to secondary pollution the environment.

According to this circumstance, Gaofu machinery push to environmentally dewater screen, supporting cyclone, it can make the drilling mud concentration, dehydration dry row, the sediment moisture content is low from dry out, can achieve dry pile, transport.

Dewater screen’s underflow mud content is low, backwater reuse can be achieved

Dewatering screen adopt dual-electrode self-synchronization technology, universal eccentric block, adjustable amplitude vibrator. The machine is combined mainly by the screen box, exciter, support system and motor. The two mutually independent vibrators are respectively driven by the tape coupling to do synchronous reverse operation. The centrifugal force generated by two eccentric masses is superposed along the vibration direction and reversely counteracted, thereby forming a single vibration force along the vibration direction, making the screen box reciprocating linear motion.

Dewatering screen, also known as high-frequency dewatering screen, changing the water surface tension of pulp through the exciting force, pulp water through the screen to become the undersize material, and fine material is blocked by the screen to form the filter layer by the vibration of the forward movement of discharge. Dewatering screen is mainly used for detailings dewatering in the mineral processing industry, coal slurry dehydration of coal preparation plant, washed quartz sand dewatering and ceramic slurry dehydration, and wet and dry classification, dehydration, removal and mud removal of medium and fine granular materials in industrial sectors such as electric power, sugar making and salt making.