Home / Solutions / Other industry solutions / Abrasive material

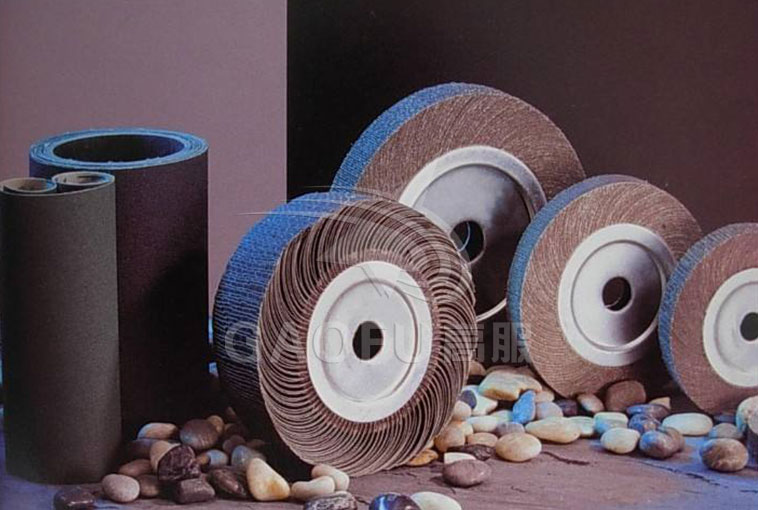

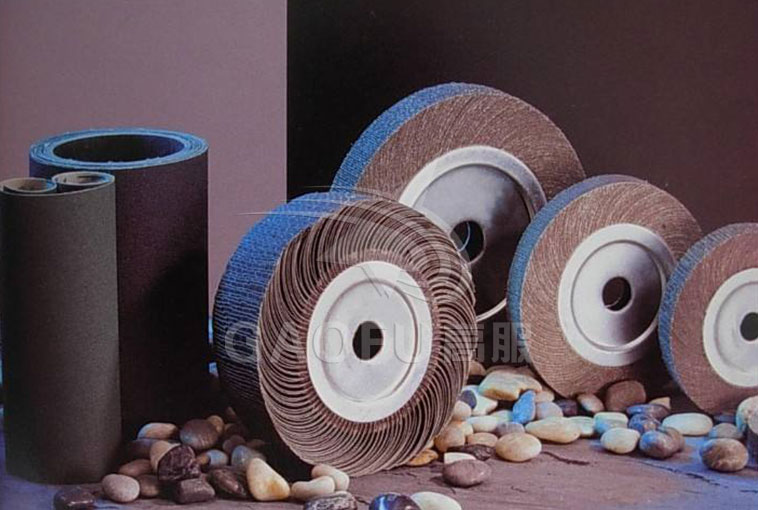

Abrasives are sharp, hard materials used to grind softer material surfaces. There are two categories of abrasives: natural abrasives and artificial abrasives. According to hardness, there are two categories: superhard abrasives and ordinary abrasives. Abrasives range from softer household detergents and gemstone abrasives to the harder material diamond. Abrasives are essential materials for making every product. Many natural abrasives have been replaced by artificial abrasives. Except for diamond, the performance of natural abrasives is not stable, but they still have their use value. Diamond is an abrasive with high hardness. It is mainly produced in South Africa, accounting for 95% of the world’s total production. The rest are Brazil, Australia, Guyana, Venezuela and other places. Industrial diamonds range from off-white to black. After being crushed, they can be made into grinding wheels, abrasive belts, polishing wheels and abrasive powder.

Abrasives are sharp, hard materials that grind softer material surfaces. Abrasives with natural abrasive and artificial abrasive two broad categories. According to the hardness of the super-hard abrasive and general extra-abrasive two categories. Abrasives range from softer household detergents, gem abrasives to the hardest material diamonds. Abrasive materials are indispensable for the manufacture of every precision product. Many natural abrasives have been replaced by artificial abrasives. In addition to diamonds, natural abrasive properties are not stable, but still its use value. Diamond is the hardest abrasive, origin South Africa, accounting for 95% of the world's total output, the rest of Brazil, Australia, Guyana and Venezuela and other places. Industrial diamond from white to black ranging from crushed grinding wheel, belt, polishing wheel and grinding powder.

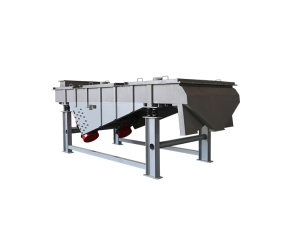

Abrasive screening equipment is Xinxiang Gaofu company in the various types of abrasive screening common noise problems, precision problems and vibrating screen wear problems, devoted themselves to the development of a dedicated linear abrasive screen, abrasive ultrasonic vibration sieve, Abrasive special ultrasonic test sieve, etc., effectively improve the accuracy of the abrasive sieve, reduce or even avoid the noise pollution generated in the process of sieving the abrasive, and greatly improve the service life of the sieve shaker, praised by customers.

Abrasive special vibrating sieve is Xinxiang Gaofu company years of wisdom combined with advanced foreign technology research and development. Divided into abrasive linear vibrating sieve, abrasive vibrating sieve and ultrasonic screening sieve three kinds:

Abrasive linear vibrating screen is the use of vibration motor vibration as a vibration source, the abrasive was thrown on the screen, while moving straight ahead, less than the mesh size of the abrasive sieve through the next level of screening, greater than the aperture of abrasive automatic discharge. Abrasive linear vibrating sieve can simultaneously produce 6 kinds of precise size abrasive materials through 5 layers of sieve. It is generally recommended to install three layers in one single unit.

Gaofu company's abrasive linear vibrating sieve according to the actual needs of users, tailored to join existing production systems, automated production. At the same time can be equipped with Gaofu research and development of special dust removal equipment to ensure clean and pollution-free production environment, and to avoid the abrasive throwing waste.

Abrasive vibration sieve is based on the traditional vibration sieve, the use of patented screen frame, abrasive grade screen designed specifically for the formation of abrasive at the same time can be graded six specifications. With Gaofu domestic leading ultrasonic screening technology, not only ensures the accurate grading of abrasive, but also solve the blocking problem, while the service life of the screen has also been extended.

Ultrasonic testing sieve is a Gaofu company for high value, small output of abrasive production or laboratory test abrasive particle size and specially designed vibrating sieve, which meets the standard test sieve standards related to accuracy, but also has the ability to increase ultrasound penetration rate , Is the perfect substitute for a impact sieve.

It has unique effects on the screening and classification of powdery and granular materials.

Gaofu combines ultrasonic and vibrating screens to solve the problem of difficult screening of highly adsorbent materials.

High screening accuracy and accurate detection results. Suitable for particle shape, particle size distribution and various detection